You're browsing Fume Extraction.

Fume Extraction

-

WELDING FUME MONITOR AEROGUARD

PN PLYAGSYSTQWS - Welding Supply Solutions| /AeroGuard AeroGuard gives you real-time transparency and assurance of the quality of your indoor air. It has a wide range of sensors, monitoring...

View full details -

VENTILATOR SET 500MM VENT & 5MT DUCTING

PN TPV500SETQWS - Welding Supply Solutions| /Suitable for air/fume extraction or blowing fresh air. Ideal ventilation for workshops and confined areas. FEATURES: Blade diameter: 500mm Flo...

View full details -

3MT X 160MM INT/SUP ARM SUITS ALFI CEILING MOUNT FILTER

PN P-053ALFI| /ALFI Flexible Fume Extraction Arms P-053 Internally supported welding fume extraction arms SELF SUPPORTING: Flexible arms with Internal / Externa...

View full details -

200MM EXTRACTION FAN SET WITH VENTILATOR AND 5M DUCT

PN JPV200-SSQWS - Welding Supply Solutions| /FEATURES: Large capacity motor with E-class of TECO / TATUNG brand motor Long endurance Specially designed axial propeller, high static pressu...

View full details -

300MM EXTRACTION FAN SET WITH VENTILATOR AND DUCT

PN 90406QWS - Welding Supply Solutions| /FEATURES: Size: 300mm Flow rate: 62m/min Static pressure: 350 pa Voltage: 220~240V Frequency: 50~60 Hz Watts: 550W Speed: 2900rpm Portabl...

View full details -

MOBIFLEX ULTRAFLEXIABLE FUME ARM 3M

PN 7925170180AQWS - Welding Supply Solutions| /Arm for Mobiflex 400-MS 7925170180A Important features Simple positioning Minimal maintenance Dent and scratch resistant material 360 ° rota...

View full details -

200MM EXTRACTION FAN SET WITH VENTILATOR AND 5M DUCT

PN TPV200SETQWS - Welding Supply Solutions| /FEATURES: Large capacity motor with E-class of TECO / TATUNG brand motor Long endurance Specially designed axial propeller, high static pressu...

View full details -

-

LINCOLN MOBIFLEX 200-M – MOBILE FUME EXTRACTOR

PN 7022110700Lincoln| /Top Features Large Capacity, Disposable Cellulose Filter Generous 735 CFM Airflow Front Casters and Rear Wheels Generous Airflow - 735 CF...

View full details -

ALFI PORTA-FLEX FUME EXTRACTION UNIT

PN P-609ALFI| /Porta-Flex 200 Portable Fume Extractor A portable filtered welding fume extractor The Porta-Flex 200 is a portable fume extractor and filter su...

View full details -

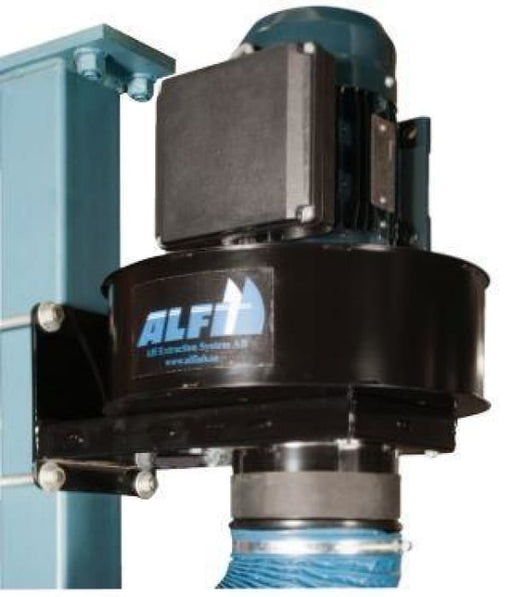

ALFI P-MAX FAN ONLY - TURBO/2100M3/HR FIO/1.1 KW/3 PHASE

PN P-032ALFI| /PMax turbo fan P-032 – 1.1kW | 3 Phase | 2100m³/hr FIO The P-Max fan is designed for extracting smoke, gas and lighter dust, and is ideal for the ...

View full details -

ALFI 240V MOBILE FILTER W/ 2MTR ARM

PN A-540KITALFI| /MF-Eco Mobile filtered fume extraction unit + 2m arm Mobile welding fume extractor with filtered air The MF-Eco Mobile Filtered Fume Extraction u...

View full details -

INTERNAL SUPPORT WALL MOUNT FUME EXTRACTION ARM 3MT X160MM

PN P-008ALFI| /FEATURES: To be Wall mounted 160mm diameter duct 3.0m arm Constructed with flexible internal support Fan/Blower NOT included - refer to PN:...

View full details -

5M SUCTION HOSE SET, WITH MAGNETIC HOOD

PN 7900068010Lincoln| /FEATURES: Flexible extraction hose with magnetic hood set Ideal for those hard to access fume extraction applications Hose is reinforced with...

View full details -

600MM PORTABLE VENTILATOR & 5M DUCTING

PN TPV600SETQWS - Welding Supply Solutions| /Suitable for air/fume extraction or blowing fresh air. Ideal ventilation for workshops and confined areas. FEATURES: Blade diameter: 600mm Flo...

View full details -

ALFI WALL MOUNTED WF-ECO JET PULSE WALL-FILTER 3-PHASE

PN P-547ALFI| /WF-ECO Jet Pulse Wall Mount Fume Extractor Wall mounted filtered welding fume extractor WF-Eco Jet Pulse filter has a very efficient built in c...

View full details -

WF ECO WALL MOUNTED FILTERED UNIT C/W FAN 1 PH MOTOR

PN P-549ALFI| /The most efficient and economical solution for welding smoke and dust extraction, the WF-Eco cleans rooms of welding fumes and fine grinding dust. ...

View full details -

ALFI EXTRACTION FAN 0.75KW 1 PHASE (INLET 160MM)

PN P-012ALFI| /ALFI Fan Pole / Wall Mount Fume Extractor Wall mounted Non-filtered welding fume extractor • Designed to fit directly onto wall bracket of ALFI...

View full details -

EXTRACTION DUCTING - 300MMX5MTR

PN 90408QWS - Welding Supply Solutions| /Extraction duct for super speed extraction fan. FEATURES: 300mm diameter 5m length duct Suitable for air/fume extraction or blowing fresh air...

View full details -

MOBIFLEX ULTRAFLEXIABLE FUME ARM 4M

PN 7925220180AQWS - Welding Supply Solutions| /Arm to suit Mobiflex Features Ultra-light flexible positioning Minimal maintenance Dent and scratch resistant material 360° ro...

View full details -

-

LINCOLN MOBIFLEX 400-M MOBILE FUME EXT

PN 7045400700Lincoln| /Includes : 6m input lead requires plug, Requires Extraction arm LFA 3.1 or LFA 4.1 or Suction hose, Requires compressed air 4 to 5bar You will nee...

View full details -

-

BINZEL FES EXTRACTION UNIT 240V 10A POWER SOURCE ONLY)

PN 601.0001.1BINZEL| /The FES 200 units come complete as standard with an auto start-stop function, which means these extraction filter units operate only when welding i...

View full details -

TRANSLAS 8XE 500 MIG DUAL EXTRACTION SYSTEM

PN TR500DTranslas| /Two person 500 amp water cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), ...

View full details -

TRANSLAS 8XE 250 MINI MIG DUAL EXTRACTION SYSTEM

PN TR250DTranslas| /Two person 250 amp air cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), ex...

View full details -

TRANSLAS 8XE 500 MIG SINGLE EXTRACTION SYSTEM

PN TR500STranslas| /500 amp water cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), extraction ...

View full details -

TRANSLAS 8XE 400 MIG DUAL EXTRACTION SYSTEM

PN TR400DTranslas| /Two person 400 amp air cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), ex...

View full details -

TRANSLAS 8XE 400 MIG SINGLE EXTRACTION SYSTEM

PN TR400STranslas| /400 amp air cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), extraction un...

View full details -

TRANSLAS 8XE 250 MINI MIG SINGLE EXTRACTION SYSTEM

PN TR250STranslas| /250 amp air cooled on-gun fume extraction system.Kit includes everything you need to get started with on-gun extraction: fume gun(s), extraction un...

View full details -

TRANSLAS 8XE EXTRACTOR EURO 500 AMP 45° 4M

PN TR8XO5060401000Translas| /The Translas 8XE 500 MIG fume extraction torch integrates the most efficient fume extraction structure in the welding industry. Combined with the C...

View full details -

TRANSLAS 8XE EXTRACTOR EURO 400 AMP 45° 4M

PN TR8XO4028401000Translas| /The Translas 8XE 400 MIG fume extraction torch integrates the most efficient fume extraction structure in the welding industry. Combined with the...

View full details -

TRANSLAS 8XE MINI EXTRACTOR EURO 250 AMP 45° 4M

PN TR8XO1000401000Translas| /The Translas 8XE MINI 250 MIG fume extraction torch integrates the most efficient fume extraction structure in the welding industry. Combined wit...

View full details -

BOMAKSAN BENCH FUME EXTRACTION SYSTEM

PN BBENCHBomaksan| /The Bomaksan BENCH combines the benefits of a mobile LEV fume extraction system with a downdraft bench and can be used across all medium-to-high ...

View full details -

XF ADVANCE SINGLE 36 4M

PN 601.K1ADV36BINZEL| /XF ADVANCE FUME EXTRACTOR SINGLE ARM 36 4 METRES 601.K1ADV36 Fume Extraction System xFUME® ADVANCEDFume extraction for up to two manual workstatio...

View full details -

XF ADVANCE DUAL 501 4M

PN 601.K2ADV501BINZEL| /XF ADVANCE FUME EXTRACTOR DUAL 501 4 METRES 601.K2ADV501 Fume Extraction System xFUME® ADVANCED Fume extraction for up to two manual workstationsIn...

View full details -

XF ADVANCE SINGLE 501 4M

PN 601.K1ADV501BINZEL| /XF ADVANCE FUME EXTRACTOR SINGLE ARM 501 4 METRES Fume Extraction System xFUME® ADVANCED Fume extraction for up to two manual workstationsIn comb...

View full details -

XF ADVANCE DUAL 36 4M

PN 601.K2ADV36BINZEL| /XF ADVANCE FUME EXTRACTOR DUAL 36 4 METRES 601.K2ADV36 Fume Extraction System xFUME® ADVANCED Fume extraction for up to two manual workstationsIn...

View full details -

BINZEL CYCLONE FUME EXTRACTION UNIT FEC C/W XFUME 36 4M

PN 601.KFECBINZEL| /FUME EXTRACTION SYSTEM 240V WITH CYCLONE TECHNOLOGY PACKAGE The mobile fume extraction system FEC combines the highest suction output and intelli...

View full details -

FEC C/W XFUME 501 4M

PN 601.KFEC501BINZEL| /FUME EXTRACTION SYSTEM 240V WITH CYCLONE TECHNOLOGY PACKAGE The mobile fume extraction system FEC combines the highest suction output and intelli...

View full details -

BINZEL CYCLONE FEC EXTRACTION UNIT 240V 10A INC 5M SUCT HOSE

PN 601.0071.1BINZEL| /Fume Extraction System 240V With Cyclone Technology 601.0071.1 The mobile fume extraction system FEC combines the highest suction output and intel...

View full details -

XFUME ADVANCED EXTRACTION UNIT 240V 15A

PN 601.0099.1BINZEL| /xFUME ADVANCED Powerful extraction system for up to two manual welding workstations. Ideally suited for RAB GRIP HE fume extraction torches. In com...

View full details -

MAIN FILTER CARTRIDGE FEC

PN 601.0075.1BINZEL| /MAIN FILTER CARTRIDGE FOR FLEX 36M2 BINZEL 601.0075.1

-

EXHAUST AIR FILTER FEC

PN 601.0077.1BINZEL$217.51 / each| /Binzel FEC Exhaust Air Filter Key Features Replacement exhaust filter for the Binzel FEC fume on torch unit. Binzel code: 601.0077.1

$217.51 / each| / -

-

-

-

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!