A Guide to Choosing the Perfect TIG Tungsten for Welding Success

Selecting the right color TIG tungsten electrode is an art form within the science of welding. By understanding the unique properties of each color and tailoring your choice to the specific welding application, you can elevate your welding game and achieve precision, reliability, and excellence in every weld. So, let's dive into the colorful world of TIG tungsten and unlock the secrets to radiant, high-quality welds.

One of the critical choices in TIG welding is selecting the appropriate tungsten electrode color for your specific application. Just like an artist selects the perfect brush for a painting, choosing the right tungsten electrode ensures a seamless weld and optimal performance. In this blog, we'll explore the different colors of TIG tungsten electrodes and guide you through selecting the ideal one for your welding needs.

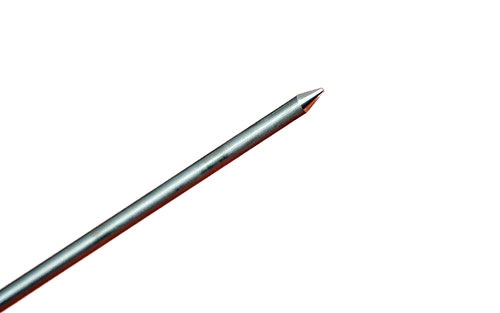

Tungsten welding electrodes

TIG welding offers the welder exceptional control, which is one of the reasons it is used for delicate welding applications. An electric arc that shoots from a tungsten electrode in the torch provides the heat needed for welding. By gradually incorporating tiny quantities of unusual elements into the tungsten, welding experts have discovered several methods to customize these electrodes for particular uses throughout the years. A colored band on one end of the electrodes is used to distinguish between the various varieties.

There were only two varieties of tungsten that were often utilized in the early days of TIG welding. For aluminum and magnesium, pure tungsten was preferred; for all other purposes, 2% thoriated tungsten was utilized. Although they were effective for many years, advancements in science and technology produced a wide variety of tungsten electrodes, each with distinct characteristics. A novice welder may find it confusing to navigate through all the alternatives, so let's look at the most popular varieties of tungsten electrodes. This ought to assist you in selecting the ideal one for your welding projects.

The TIG procedure originated in the 1940s with the use of pure tungsten as a welding electrode. Since pure tungsten has the greatest melting temperature of any metal, it made logical to use it when TIG welding was invented as an effective way to combine aluminum and magnesium alloys. Back then, power supplies were transformer-based, and pure tungsten could be used for AC mode welding—the industry standard for joining aluminum and magnesium. It was standard procedure to "ball" the tip of the tungsten in those days. To do this, the power source was switched to the "reverse polarity" (electrode positive) mode and a brief burst of current was sent through the electrode. This would melt the electrode tip, and the tungsten would form into a smooth, glossy ball when the current was cut off. The amount of current sent through the electrode in the EP mode was able to control the size of the ball, and the shielding gas kept the electrode from oxidizing. The arc would be shaped into a broad cone by this balled electrode, which could also carry reasonably high current without "spitting," or spitting minute bits of tungsten into the weld puddle. Be aware that pure tungsten electrodes are not advised while using contemporary inverter power sources.

In DC welding, which is utilized for all metals except magnesium and aluminum, 2% or less of thorium was added to the tungsten electrode. This improved the electrode's ability to transport current and led to more regular arc beginnings. For good reason, these two types of electrodes are not frequently employed with contemporary welding equipment, despite serving TIG welders' demands for decades. The industry switched from using transformer power sources to inverter power sources, which eliminated the need to ball the electrode for AC welding and replaced pure tungsten electrodes with better mixtures.

Thorium is slightly radioactive and handling thoriated tungsten electrodes poses health and environmental risks at elevated exposure levels. Consult the AWS Safety and Health Fact Sheet on Thoriated Tungsten Electrodes for more information. Other elements have proven to be superior to thorium for electrodes in every way. As you’ll see, there are a couple types of tungsten electrodes that are well suited for virtually any TIG welding task, either AC or DC

What is a Tungsten and what's it made of?

Every tungsten is composed of around 95%+ pure tungsten, which was formerly the only sort available, with a little amount of other components added for improved performance in particular areas.

Since thoriated tungstens were the second kind of tungsten to be made accessible, they are frequently used as a benchmark to compare the performance of other, more recent tungstens.

Understanding TIG Tungsten Electrodes:

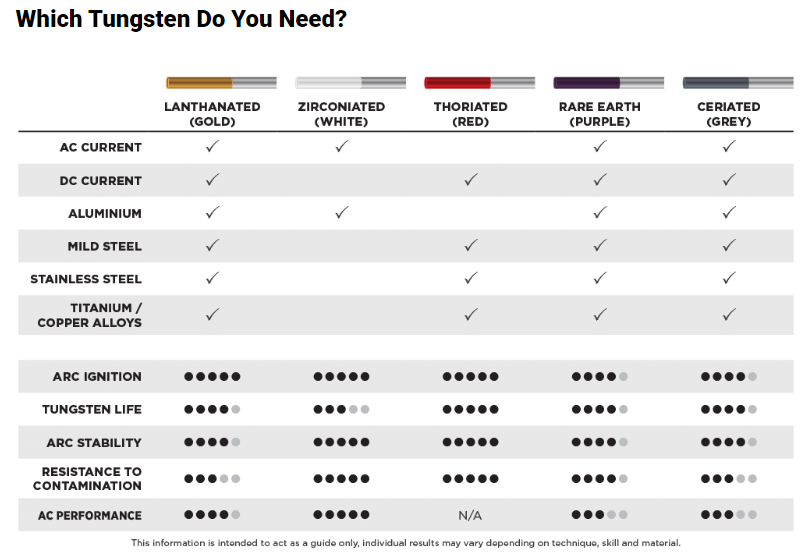

The Color Spectrum:

2% lanthanated tungsten (color-coded blue) is at the top of the list. This is a true all-purpose electrode, with excellent arc starting characteristics and the ability to transmit high current without spitting. It provides a stable arc at both high and low current, and works very well on all metals.

2% Ceriated tungsten (grey) is another good choice for all types of welding; providing good arc start and restart characteristics with no spitting. It is ideal for low- and medium-current welding on all metals.

Rare earth tungsten (chartreuse) has the very best low-current arc starting characteristics, and it can be used on all metals. This type is often preferred for automated welding.

Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. It has high current-carrying capacity, and it provides better arc starts and stability than pure tungsten.

Tungsten electrodes available in a wide variety of sizes — from.020 to ¼ inch. You must choose a diameter large enough to accommodate the maximum current required for each welding task. At extremely low amperage levels, electrodes with a smaller diameter will initiate the arc faster. I utilize a 3/32-inch diameter electrode for my work, which includes a wide variety of forms and sizes. I can weld metals up to ¼-inch thick and handle arc starts for light-gauge sheet metal with ease.

The most typical length for tungsten electrodes is seven inches. Cutting them down may be advantageous when working in confined places, allowing for a shorter back cap on the torch.

The most typical length for tungsten electrodes is seven inches. Cutting them down may be advantageous when working in confined places, allowing for a shorter back cap on the torch.

Tungsten can be cut using an abrasive cutoff wheel or ground through using the corner of a grinding wheel. Do not use a wire cutter to cut or bend the electrodes. This might result in hidden fractures at the cut ends, causing an irregular arc.

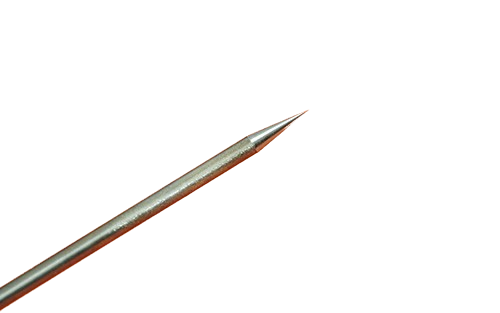

Tungsten electrodes normally have blunt edges that must be sharpened before use. The angle of the point dictates the form of the arc emanating from the electrode. The electrode tip angle and the arc have an inverse connection; a sharply pointed electrode produces a cone-shaped arc with a broad base when it hits the metal, resulting in a large puddle. This can be useful for edge welding thin materials.

In contrast, a stubby tip on your tungsten will create a narrow cone with a short base, concentrating the energy in a smaller region. This might help you achieve deep penetration through thicker materials. With some testing, you may determine the point angle that produces the optimum features for a certain work.

In contrast, a stubby tip on your tungsten will create a narrow cone with a short base, concentrating the energy in a smaller region. This might help you achieve deep penetration through thicker materials. With some testing, you may determine the point angle that produces the optimum features for a certain work.

For very high-amperage welding, grinding a little flat near the tip of the tungsten electrode can be useful. This will assist to keep the electrode from spewing tiny particles into the workpiece.

Although there are several instruments designed expressly for sharpening tungsten electrodes, a stone, belt, or disc grinder will suffice. To avoid contaminating the electrode, use a tungsten-specific grinder and ensure that all grinding scratches are parallel to the electrode's centerline. If you leave angled or spiral grinding scratches, the arc may become unstable.

Electrodes frequently become polluted. This can happen if the tip accidently touches the molten puddle or if the filler rod makes contact with the hot electrode. Impurities in or on the metal may occasionally fly out and pollute the electrode as well. It is critical that the electrode be completely free of contamination, thus be prepared to replace it out anytime this occurs. Having numerous pre-sharpened electrodes on hand might be useful during welding.

Even though there are several options for tungsten welding electrodes, once you've chosen the right type and diameter for your application, you shouldn't have to worry about it much. For most welders, a decent all-purpose electrode, such as a 3/32-inch diameter, 2% lanthanated, should suffice.

the selection of the right color and diameter of TIG tungsten electrodes is paramount in welding applications. The color denotes the type of tungsten, which directly impacts the welding process and the characteristics of the weld. Additionally, choosing the correct diameter ensures optimal arc stability, control, and penetration. Moreover, meticulous tungsten electrode preparation, including proper sharpening and conditioning, is essential for achieving high-quality welds with minimal defects and ensuring consistent performance. Neglecting these crucial aspects can lead to compromised weld quality, increased rework, and potential safety hazards. Therefore, prioritizing the careful selection and preparation of TIG tungsten electrodes is indispensable for achieving successful welding outcomes and ensuring operational efficiency in various applications.