You're browsing Stud Welding Machines.

Stud Welding Machines

-

TAYLOR STUD WELDING UNIT 2 - 10MM

PN CDM10Taylor| /Taylor Stud Welding Unit 2 - 10mm: Premium Performance and Durability in Stud Welding The Taylor Stud Welding Unit 2 - 10mm is engineered for preci...

View full details -

TAYLOR STUD WELDING UNIT 2 - 8MM

PN CDM8Taylor| /The CDM capacitor discharge stud welding machines range is both highly cost-effective and reliable, providing powerful welding action that is fas...

View full details -

TAYLOR DRAWN ARC STUD WELDER DA2700

PN DA2700Taylor| /The TAYLOR DRAWN ARC STUD WELDER DA2700 is a high-performance industrial welding machine designed for precision welding of various metal studs onto...

View full details -

TAYLOR DRAWN ARC STUD WELDER I16 INVERTER W/ DA3A TORCH

PN I16 DATaylor| /The Taylor Drawn Arc Stud Welder I16 Inverter with DA3A Torch is a high-performance welding system designed for industrial applications requiring p...

View full details -

TAYLOR DRAWN ARC STUD WELDER I12 INVERTER W/ DA2A TORCH

PN I12 DATaylor| /The Taylor Drawn Arc Stud Welder I12 Inverter with DA2A Torch is a high-performance, industrial-grade welding system designed for precision stud we...

View full details

QWS: Your Ultimate Source for Stud Welders and Accessories

At QWS, we understand the importance of reliable and efficient stud welding equipment for a wide range of industries and applications. As a trusted supplier of welding solutions, we offer a comprehensive selection of stud welders and accessories to meet your specific needs.

Our stud welders are meticulously designed and manufactured to deliver exceptional performance, durability, and ease of use. Whether you require a portable stud welder for on-site projects or a high-capacity system for industrial applications, we have you covered. Our extensive range includes capacitor discharge (CD) stud welders and arc stud welders, ensuring that we have the perfect solution for your stud welding requirements.

When you choose QWS, you can expect top-notch quality and precision. Our stud welding machines are equipped with advanced features and cutting-edge technology to ensure precise and consistent welds. With adjustable settings, user-friendly interfaces, and quick setup capabilities, our stud welders streamline the welding process, saving you time and effort.

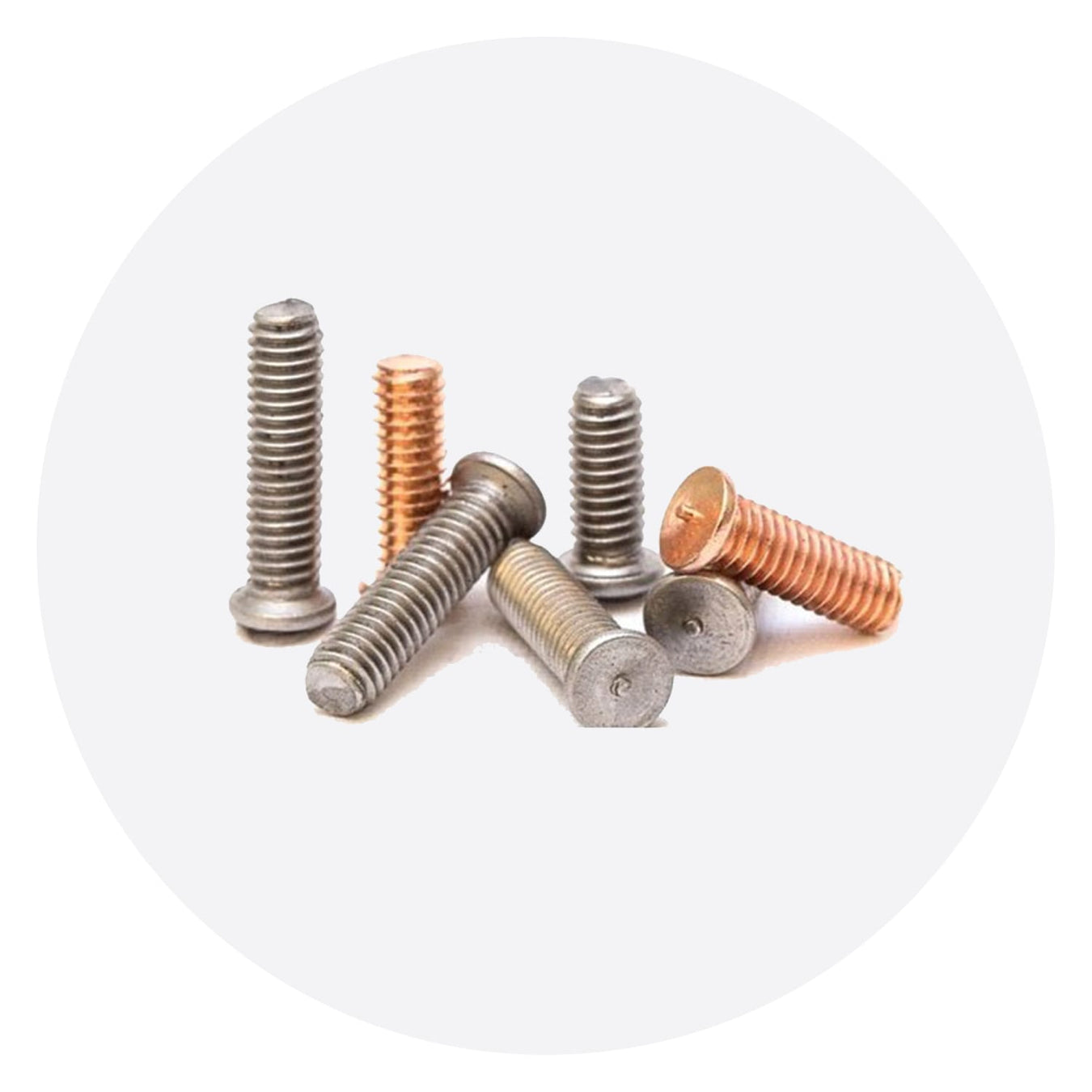

In addition to our stud welding machines, we offer a wide range of accessories to enhance your welding experience. From stud welding guns and cables to collets and weld studs, we provide all the necessary components to complete your stud welding projects efficiently. Our accessories are carefully selected to ensure compatibility and optimal performance with our stud welders.

At QWS, we pride ourselves on not only providing top-quality products but also delivering exceptional customer service. Our team of knowledgeable experts is always ready to assist you in finding the right stud welding solution for your specific application. We understand that every project is unique, and we are dedicated to offering personalized guidance and support throughout your purchasing journey.

Whether you are a professional welder, contractor, or a business in need of stud welding solutions, QWS is your go-to source. With our extensive inventory, reliable performance, and outstanding customer service, we strive to be your trusted partner in the welding industry. Experience the QWS difference and take your stud welding capabilities to the next level.

Contact us today or browse our website to explore our comprehensive range of stud welders and accessories. Trust QWS for all your stud welding needs!

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!