Why 16mm is the practical limit for stud welding on vertical surfaces

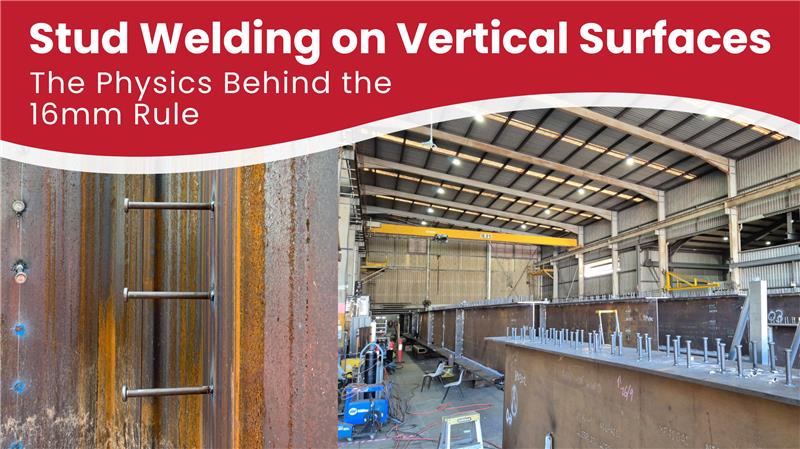

Stud welding is a widely used technique in construction, steel fabrication, and industrial projects. It provides a strong, permanent bond between metal fasteners and steel surfaces. However, when it comes to vertical stud welding, the process becomes significantly more challenging.

Below are few of the usual vertical stud welding challenges & why most field experts considers the 16mm stud welding limit

.

The Physics Behind Vertical Stud Welding

When stud welding on vertical surfaces, gravity works against the molten metal pool and the stud itself. Larger studs require more heat and longer weld times, which means the molten metal stays fluid longer. This increases the risk of sagging, incomplete fusion, and weld failure.

Why 16mm Is the Upper Limit

Field experience and testing show that 16mm studs are the largest size that can be welded vertically with any reasonable success rate. Even under perfect conditions—stable power, correct settings, and skilled operators—achieving a strong weld at this size is extremely difficult. Our trials revealed approximately 20% failure rate for 16mm studs on vertical surfaces.

Challenges with Larger Studs

When working with larger-diameter studs in vertical positions, several difficulties commonly arise.

• Heat Control: Higher amperage and longer weld times make it harder to maintain a stable molten pool.

• Gravity Effect: Molten metal tends to flow downward, reducing adhesion at the top.

• Alignment Issues: Heavy studs are harder to keep perpendicular during welding.

Why 12mm Is the Safer Choice

For most vertical applications, 12mm studs deliver a much higher success rate. They require less heat, shorter weld times, and are easier to control, resulting in consistent adhesion and fewer failures therefore it is considered as the maximum best stud size for vertical welding.

Best Practices for Vertical Stud Welding

• Use high-quality stud welding equipment and generators for stable power.

• Ensure clean surfaces free from rust, paint, or contaminants.

• Consider pre-heating thicker materials to improve fusion.

• Perform test welds before production runs.

While welding 16mm studs vertically is technically possible, it’s not practical for most projects due to higher stud welding failure rate and difficulty achieving consistent results. For reliability and efficiency, 12mm studs remain the recommended maximum size for vertical stud welding.

At QWS, we understand that every project demands precision, reliability, and the right expertise. That’s why we provide both construction stud welding tips & industrial stud welding solutions designed to help professionals tackle complex welding challenges with confidence. Whether you're working on large-scale infrastructure or specialized fabrication, QWS delivers the guidance, equipment, and support you need to achieve strong, consistent results every time.