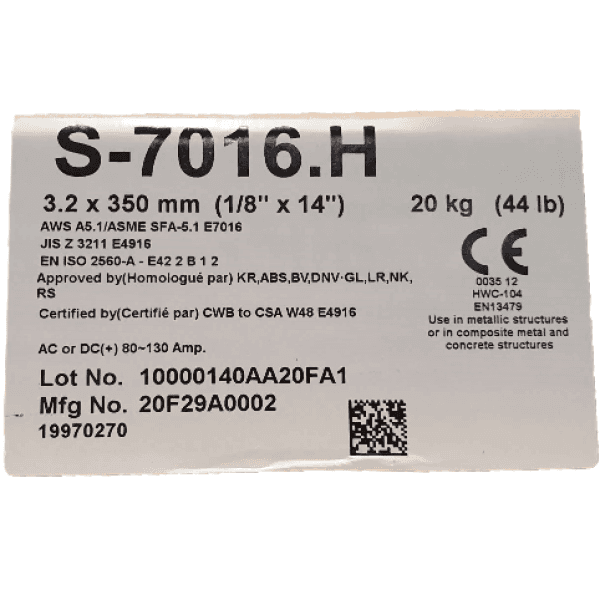

ELECTRODE 7016.H LOW HYDROGEN 3.2MM

Volume Discounts for ABN / Account holders -

Availability: 40 In stock, ready to be shipped!

Hyundai S-7016.H Low Hydrogen Electrodes – 3.2mm: Premium Welding Solution for High Tensile Steel

The Hyundai S-7016.H Low Hydrogen Electrode (3.2mm) is engineered for high-performance welding in demanding applications, such as bridges, buildings, shipbuilding, high-pressure vessels, and rolling stock. This low hydrogen electrode ensures exceptional weld quality with superior crack resistance and X-ray performance, making it the ideal choice for high tensile steel welding.

Key Features:

- Soft Stable Arc: The S-7016.H electrode ensures a smooth, consistent arc, reducing spatter and improving weld appearance.

- Smooth Appearance: Results in clean, aesthetically pleasing welds with minimal post-weld cleaning.

- No Undercut Formation: Prevents undercutting, offering a stronger and more reliable joint.

- Excellent Slag Removability: The slag has good fluidity, making it easy to remove, ensuring a clean finish.

- Superior Mechanical Properties: With high tensile strength and excellent elongation, this electrode guarantees solid performance under stress.

- Crack Resistance & X-ray Performance: Designed for optimal crack resistance, it excels in critical applications requiring X-ray inspection.

Usage Guidelines:

- Preheat: Dry electrodes at 300–350°C (572–662°F) for 60 minutes before use to maintain low hydrogen content and avoid cracking.

- Arc Starting: Use the back step method or strike the arc on a small steel plate to prevent blowholes during arc initiation.

- Wind Protection: Ensure a windscreen is used in windy conditions to prevent arc instability and ensure quality welds.

Welding Positions:

- F, HV, VU, OH: Suitable for a range of positions including flat, horizontal vertical, vertical up, and overhead welding.

Current Type:

- AC or DC±: Compatible with both AC and DC welding machines for versatile operation.

Chemical Composition (Typical Weld Metal):

- Carbon (C): 0.07%

- Silicon (Si): 0.55%

- Manganese (Mn): 1.13%

- Phosphorus (P): 0.017%

- Sulfur (S): 0.011%

Mechanical Properties (Typical Weld Metal):

- Yield Strength (Y.S): 490 N/mm² (71,100 lbs/in²)

- Tensile Strength (T.S): 600 N/mm² (87,100 lbs/in²)

- Elongation (EL.): 30.3%

- Impact Toughness at -29°C (-20°F): 80 J (59 ft.lbs)

Approvals:

- Recognized and approved by major classification societies including KR, ABS, LR, BV, DNV, GL, and NK.

Note: This product is priced per kilogram, and the minimum purchase quantity is based on the specified pack size.

Why Choose Hyundai S-7016.H Low Hydrogen Electrodes?

Whether you're welding high-tensile steels in construction, shipbuilding, or heavy-duty pressure vessels, the Hyundai S-7016.H Low Hydrogen Electrode offers reliable, high-quality results with minimal defects. Its strong mechanical properties and excellent crack resistance make it an essential tool for structural and critical welds that demand precision and durability.