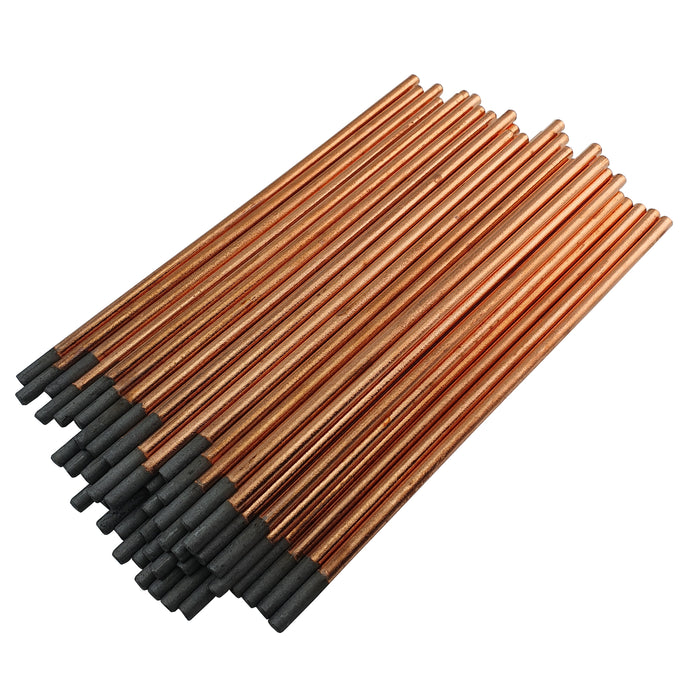

CARBON ARC DC GOUGING RODS 8.0MM 50/PKT

Volume Discounts for ABN / Account holders -

Availability: 7 In stock, ready to be shipped!

Arc-Air DC Gouging Carbons: Description and Applications

Arc-Air DC gouging carbons are engineered for precision metal removal by combining carbon/graphite with a binder, followed by baking and coating with a controlled layer of copper. The copper coating enhances electrical conductivity, ensuring efficient and cooler operation. These carbons are available in three types: Pointed, Jointed, and Flat.

-

Pointed Carbons: These are versatile, all-purpose gouging electrodes. The controlled copper coating ensures better conductivity, leading to cooler operation and more stable arc performance. The coating also helps maintain the electrode’s diameter at the arc point.

-

Jointed Carbons: Designed to prevent stub loss, each rod has a female socket and a matching male tang, enabling continuous usage without interruptions. These carbons are ideal for both semi-automatic and fully automatic torches.

-

Flat Carbons: Specially crafted for precision metal removal and scarfing applications, flat carbons produce rectangular grooves, perfect for close-tolerance tasks.

Applications:

Arc-air gouging can be performed in various positions, including downhand, vertical, horizontal, and overhead. Typically, the gouging electrode is set at an angle of 35 degrees with a stick-out length of 180mm. The groove width will be approximately 3mm wider than the electrode diameter. By adjusting the travel speed, the operator can control groove depth, with slow speeds producing deep grooves and faster speeds resulting in shallow grooves.

Air-carbon arc gouging is suitable for removing metal from a wide range of ferrous and non-ferrous materials. The air flow must be activated before starting the gouging process, and operators must wear appropriate safety gear, including eye protection (shade 12-14), ear protection, and flame-resistant clothing.

Benefits of Arc-Air DC Gouging Carbons:

- Fast and Clean Operation: Ensures smooth and hassle-free gouging with minimal interruptions.

- Versatile: Can be used on a wide variety of metals, including ferrous and non-ferrous.

- DC Operation: Specifically designed for efficient DC applications.

- Superior Arc Stability: Improved copper coating ensures stable and efficient arc performance.

Conditioning and Maintenance:

To maintain optimal performance, Arc-Air gouging carbons should be stored in a dry environment. If the carbons become damp, they must be re-dried at 180°C for 10 hours to prevent shattering during use.

High-Efficiency Gouging Carbons:

Arc-Air’s high-efficiency gouging carbons are a step forward in carbon technology, offering enhanced performance. These carbons feature a reduced carbon content and an increased copper coating, enabling them to handle up to 800 amps of current, a 25% improvement in carrying capacity. They also offer up to 10% more metal removal, with improved stick-out length and better current flow due to their fluted exterior design.

These advanced carbons are ideal for high-performance applications, delivering superior efficiency, increased durability, and enhanced metal removal capacity.

For best results, operators should always follow proper usage guidelines and maintain appropriate safety standards.