You're browsing TIG TUNGSTEN ELECTRODES.

TIG TUNGSTEN ELECTRODES

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

TUNGSTENS ZIRCONIATED - ALUM WHITE 2.4MM

PN 700-0034QWS - Welding Supply Solutions$56.00 /pack of 10$5.60 / each| /Tungstens Zirconiated - Alum White 2.4mm: High-Performance Electrode for AC Welding Zirconiated tungsten electrodes, classified as EWZr-1 by AWS st...

View full details$56.00 /pack of 10$5.60 / each| /pack of 10 -

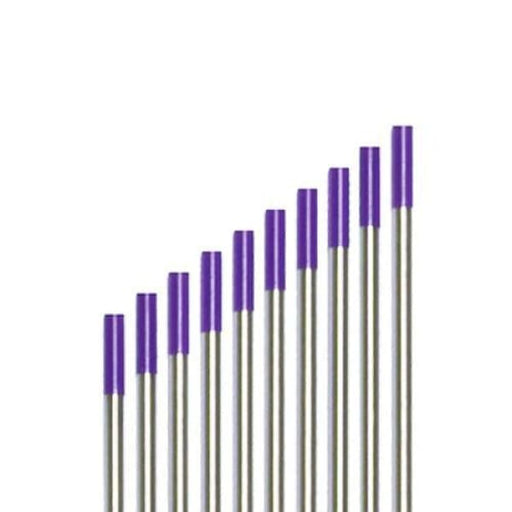

TUNGSTEN RARE EARTH E3 PURPLE TIPPED 2.4MM

PN 700-0308QWS - Welding Supply Solutions$49.80 /pack of 10$4.98 / each| /Tungsten E3 Purple-Tipped 2.4mm Electrode: The Future of Non-Radioactive Welding The Tungsten E3 Purple-Tipped 2.4mm electrode stands as a superior...

View full details$49.80 /pack of 10$4.98 / each| /pack of 10 -

TUNGSTENS THORIATED RED 2.4MM SUIT STAINLESS OR MILD STEEL

PN 700-0090QWS - Welding Supply Solutions$42.00 /pack of 10$4.20 / each| /Tungsten Thoriated Red 2.4mm Suit for Stainless or Mild Steel Product DescriptionDiscover the superior performance of Tungsten Thoriated Red 2.4mm ...

View full details$42.00 /pack of 10$4.20 / each| /pack of 10 -

TUNGSTENS THORIATED RED 1.6MM SUIT STAINLESS OR MILD STEEL

PN 700-0080QWS - Welding Supply Solutions$21.90 /pack of 10$2.19 / each| /Tungstens Thoriated Red 1.6mm - Ideal for Stainless and Mild Steel Welding The Tungsten Thoriated Red 1.6mm electrodes are highly popular for their...

View full details$21.90 /pack of 10$2.19 / each| /pack of 10 -

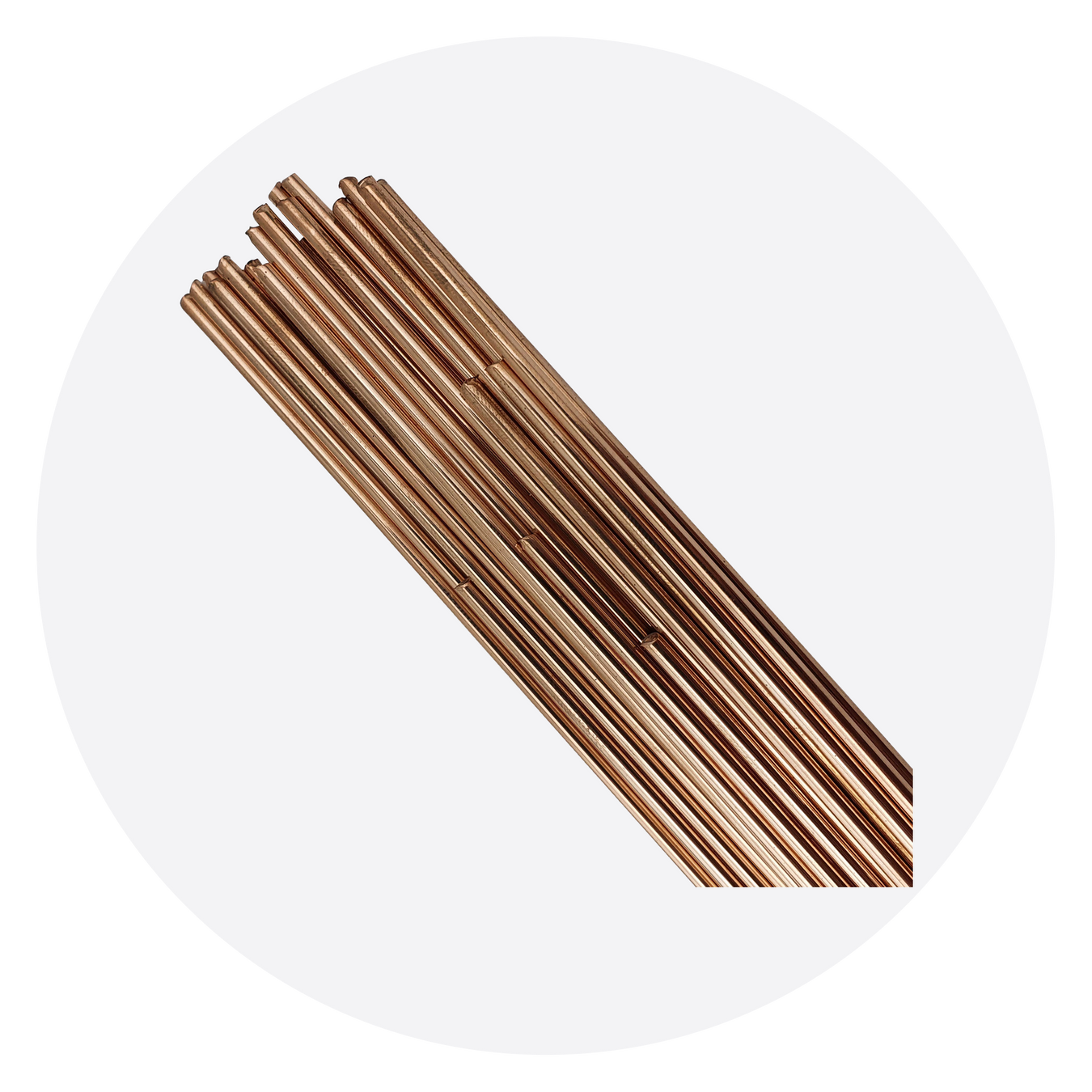

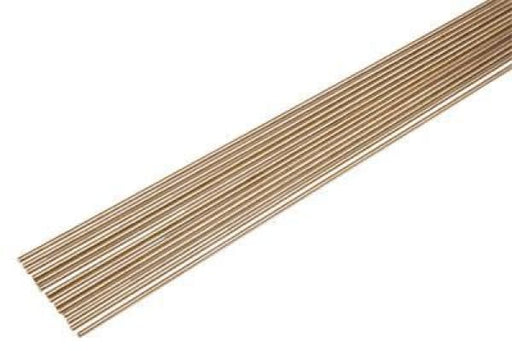

TIG FILLER WIRE 5356 ALUMINIUM 5% MAGNES. 2.4MM

PN T535624QWS - Welding Supply Solutions$120.60 /5kg Pkt$24.12 / kg| /TIG Filler Wire 5356 Aluminium 5% Magnesium, 2.4mm – High-Performance Welding Wire for Superior Strength and Corrosion Resistance TIG Filler Wire 5...

View full details$120.60 /5kg Pkt$24.12 / kg| /5kg Pkt -

TUNGSTEN RARE EARTH E3 PURPLE TIPPED 1.6MM

PN 700-0306QWS - Welding Supply Solutions$29.50 /pack of 10$2.95 / each| /The new tungsten electrode that will eventually become the number one tungsten as Thoriated electrodes become harder to import due to the ...

View full details$29.50 /pack of 10$2.95 / each| /pack of 10 -

TIG FILLER WIRE 4043 ALUM - 5% SILICON 2.4MM

PN T404324QWS - Welding Supply Solutions$119.30 /5kg Pkt$23.86 / kg| /High-Performance TIG Filler Wire 4043 - 5% Silicon 2.4mm Product Description: Upgrade your welding projects with our TIG Filler Wire 4043, speciall...

View full details$119.30 /5kg Pkt$23.86 / kg| /5kg Pkt -

TIG FILLER WIRE ST-50.6 MILD STEEL ER70-S6 2.4MM PER KG

PN T70S624QWS - Welding Supply Solutions$39.05 /5kg Pkt$7.81 / kg| /TIG Filler Wire ST-50.6 Mild Steel ER70-S6 2.4mm per KG - High-Quality Welding Solution The TIG Filler Wire ST-50.6 Mild Steel ER70-S6 2.4mm is an ...

View full details$39.05 /5kg Pkt$7.81 / kg| /5kg Pkt -

TIG FILLER WIRE 308L FOR 304 STAINLESS 1.6MM

PN T30816QWS - Welding Supply Solutions$97.75 /5kg Pkt$19.55 / kg| /Low carbon 19Cr/10Ni type filler rod recommended for TIG and oxy-acetylene welding of 304 and 304L stainless steels. Applications include...

View full details$97.75 /5kg Pkt$19.55 / kg| /5kg Pkt -

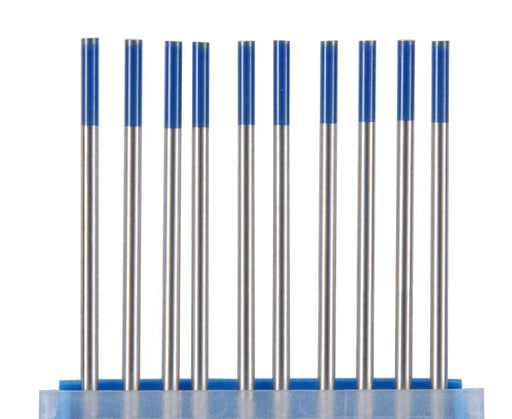

TUNGSTEN LANTHANATED 2% 2.4MM ECONOMY BLUE TIP

PN 24LQWS - Welding Supply Solutions$40.20 /pack of 10$4.02 / each| /Tungsten Lanthanated 2% 2.4mm Economy Blue Tip Electrodes – Premium Performance for Precision Welding The Tungsten Lanthanated 2% 2.4mm Economy Blu...

View full details$40.20 /pack of 10$4.02 / each| /pack of 10 -

TIG FILLER WIRE ST-72 SUPER STEEL 1.6MM ER70S-2

PN T70S216QWS - Welding Supply Solutions$47.75 /5kg Pkt$9.55 / kg| /TIG Filler Wire ST-72 Super Steel 1.6MM ER70S-2: High-Quality Welding Solution General OverviewThe TIG Filler Wire ST-72 Super Steel 1.6MM ER70S-2 ...

View full details$47.75 /5kg Pkt$9.55 / kg| /5kg Pkt -

TUNGSTENS CERIATED GREY TIP - ALL PURPOSE 2.4MM

PN 700-0169QWS - Welding Supply Solutions$32.10 /pack of 10$3.21 / each| /Ceriated tungsten electrodes contain a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. These electrodes perform best in DC welding at...

View full details$32.10 /pack of 10$3.21 / each| /pack of 10 -

TIG FILLER WIRE 5356 ALUMINIUM 5% MAGNES. 1.6MM

PN T535616QWS - Welding Supply Solutions$99.90 /5kg Pkt$19.98 / kg| /TIG Filler Wire 5356 Aluminium 5% Magnesium 1.6mm - Premium Quality for Precision Welding The TIG Filler Wire 5356 Aluminium 5% Magnesium 1.6mm is ...

View full details$99.90 /5kg Pkt$19.98 / kg| /5kg Pkt -

TIG FILLER WIRE ST-50.6 MILD STEEL ER70S-6 1.6MM PER KG

PN T70S616QWS - Welding Supply Solutions$43.20 /5kg Pkt$8.64 / kg| /Product Description: TIG Filler Wire ST-50.6 Mild Steel ER70S-6 1.6mm per KG Introducing our high-performance TIG Filler Wire ST-50.6, made from mi...

View full details$43.20 /5kg Pkt$8.64 / kg| /5kg Pkt -

TIG FILLER WIRE 4043 ALUM - 5% SILICON 3.2MM

PN T404332QWS - Welding Supply Solutions$114.95 /5kg Pkt$22.99 / kg| /High-Performance Aluminum / Silicon TIG Welding Rod: ER4043 is a 5% Silicon Aluminum filler metal that is used primarily for welding Alu...

View full details$114.95 /5kg Pkt$22.99 / kg| /5kg Pkt -

TIG FILLER WIRE ST-72 SUPER STEEL 2.4MM ER70S-2

PN T70S224QWS - Welding Supply Solutions$41.85 /5kg Pkt$8.37 / kg| /TIG Filler Wire ST-72 Super Steel 2.4mm ER70S-2 Product Overview: The ST-72 Super Steel TIG Filler Wire, 2.4mm ER70S-2, is a premium, copper-coated...

View full details$41.85 /5kg Pkt$8.37 / kg| /5kg Pkt -

TUNGSTENS ZIRCONIATED - ALUM WHITE 3.2MM

PN 700-0036QWS - Welding Supply Solutions$65.40 /pack of 10$6.54 / each| /Tungstens Zirconiated - Alum White 3.2mm: High-Performance Welding Electrode for AC Applications The Tungstens Zirconiated - Alum White 3.2mm is a ...

View full details$65.40 /pack of 10$6.54 / each| /pack of 10 -

TUNGSTEN LANTHANATED 2% 2.4MM GERMAN MADE GOLD TIP

PN 24WL20QWS - Welding Supply Solutions$186.00 /pack of 10$18.60 / each| /Lanthanated tungsten electrodes contain a minimum of 97.80% tungsten and 1.30 to 1.70% lanthanum, or lanthana. These electrodes have exce...

View full details$186.00 /pack of 10$18.60 / each| /pack of 10 -

TIG FILLER WIRE 309L 1.6MM STAINLESS/MILD STEEL

PN T30916QWS - Welding Supply Solutions$133.00 /5kg Pkt$26.60 / kg| /Used for joining mild steel to stainless steel & also different grades of stainless steels together, 309 grade is a good 'all ...

View full details$133.00 /5kg Pkt$26.60 / kg| /5kg Pkt -

TIG FILLER WIRE 308L FOR 304 STAINLESS 2.4MM

PN T30824QWS - Welding Supply Solutions$48.95 /5kg PktTranslation missing: en.product.item.price.current $9.79 / kg| /Low carbon 19Cr/10Ni type filler rod recommended for TIG and oxy-acetylene welding of 304 and 304L stainless steels. Applications include...

View full details$48.95 /5kg PktTranslation missing: en.product.item.price.current $9.79 / kg| /Save 28% Save %5kg Pkt -

TIG FILLER WIRE ER347 STAINLESS STEEL 1.6MM

PN T34716QWS - Welding Supply Solutions$148.00 /5kg Pkt| /High-Performance Stainless Steel TIG Welding Rod: ER347 is used for welding AISI types 304, 304L, 321 and 347 where maximum corrosion r...

View full details -

TIG FILLER WIRE SILICON BRONZE 1.6MM

PN TSIBR16QWS - Welding Supply Solutions$289.10 /5kg Pkt$57.82 / kg| /A bare filler metal for fabricating and joining silicon bronze, copper alloys, some iron-base metals, and thin gauge galvanized steel. De...

View full details$289.10 /5kg Pkt$57.82 / kg| /5kg Pkt -

TIG FILLER WIRE MNMO ER80S-D2 1.6MM

PN T80SD216QWS - Welding Supply Solutions$150.00 /5kg Pkt$30.00 / kg| /Applications Fabrication of higher strength steels for use in the stress relieved condition. For offshore oil well-head process pipework...

View full details$150.00 /5kg Pkt$30.00 / kg| /5kg Pkt -

TIG FILLER WIRE 5356 ALUMINIUM 5% MAGNES. 3.2MM

PN T535632QWS - Welding Supply Solutions$113.90 /5kg Pkt$22.78 / kg| /TIG Filler Wire 5356 Aluminium 5% Magnesium – 3.2mm Overview Introducing our high-quality TIG Filler Wire 5356 Aluminium 5% Magnesium in a 3.2mm di...

View full details$113.90 /5kg Pkt$22.78 / kg| /5kg Pkt -

TIG FILLER WIRE 316L STAINLESS STEEL 1.0MM

PN T31610QWS - Welding Supply Solutions$159.40 /5kg Pkt$31.88 / kg| /TIG Filler Wire 316L Stainless Steel 1.0mm – Corrosion Resistant & High-Performance Welding Solution The TIG Filler Wire 316L Stainless Steel 1...

View full details$159.40 /5kg Pkt$31.88 / kg| /5kg Pkt -

TUNGSTENS CERIATED GREY TIP - ALL PURPOSE 1.6MM

PN 700-0167QWS - Welding Supply Solutions$32.40 /pack of 10$3.24 / each| /Ceriated tungsten electrodes contain a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. These electrodes perform best in DC welding at...

View full details$32.40 /pack of 10$3.24 / each| /pack of 10 -

TUNGSTENS THORIATED RED 3.2MM SUIT STAINLESS OR MILD STEEL

PN 700-0099QWS - Welding Supply Solutions$98.80 /pack of 10$9.88 / each| /2% thoriated tungsten electrodes contain a minimum of 97.30% tungsten and 1.70 to 2.20% thorium. They are the most commonly used electrode...

View full details$98.80 /pack of 10$9.88 / each| /pack of 10 -

TUNGSTENS THORIATED RED 1.0MM SUIT STAINLESS OR MILD STEEL

PN 700-0070QWS - Welding Supply Solutions$24.50 /pack of 10$2.45 / each| /2% thoriated tungsten electrodes contain a minimum of 97.30% tungsten and 1.70 to 2.20% thorium. They are the most commonly used electrode...

View full details$24.50 /pack of 10$2.45 / each| /pack of 10 -

TUNGSTENS ZIRCONIATED - ALUM WHITE 1.6MM

PN 700-0030QWS - Welding Supply Solutions$32.50 /pack of 10$3.25 / each| /Zirconiated tungsten electrodes (AWS classification EWZr-1) contain a minimum of 99.10% tungsten and .15 to .40% zirconium. A Zirconiated ...

View full details$32.50 /pack of 10$3.25 / each| /pack of 10 -

TIG FILLER WIRE CIGWELD COMWELD 308L 1.6MM

PN 321406Cigweld$715.25 /5kg Pkt$143.05 / kg| /General Comweld 308L stainless steel is a high quality low carbon rod for the Gas or Gas Tungsten Arc (TIG) welding of a wide...

View full details$715.25 /5kg Pkt$143.05 / kg| /5kg Pkt -

TUNGSTEN LANTHANATED 2% 3.2MM ECONOMY BLUE TIP

PN TR0014-32QWS - Welding Supply Solutions$64.00 /pack of 10$6.40 / each| /$64.00 /pack of 10$6.40 / each| /Sold outpack of 10 -

TIG FILLER WIRE SILICON BRONZE 3.2MM

PN TSIBR32QWS - Welding Supply Solutions$225.10 /5kg Pkt$45.02 / kg| /A bare filler metal for fabricating and joining silicon bronze, copper alloys, some iron-base metals, and thin gauge galvanized steel. De...

View full details$225.10 /5kg Pkt$45.02 / kg| /5kg Pkt -

TIG FILLER WIRE DE-OX COPPER ERCU 2.4MM

PN TCU24QWS - Welding Supply Solutions$243.70 /5kg Pkt$48.74 / kg| /DEOX Copper is a 98% copper filler metal used for MIG, TIG and oxyacetylene welding of copper and copper-alloyed base metals. DEOX Copper...

View full details$243.70 /5kg Pkt$48.74 / kg| /5kg Pkt -

TIG FILLER WIRE CROMO 1 ER80S-B2 2.4MM

PN T80SB224QWS - Welding Supply Solutions$235.40 /5kg Pkt$47.08 / kg| /A low-alloy copper coated TIG filler rod with 1.25% Cr and 0.5% Mo content to be used for the welding of creep resistant steels. Also su...

View full details$235.40 /5kg Pkt$47.08 / kg| /5kg Pkt -

TIG FILLER WIRE 4043 ALUM - 5% SILICON 1.6MM

PN T404316QWS - Welding Supply Solutions$141.60 /5kg Pkt$28.32 / kg| /High-Performance Aluminum / Silicon TIG Welding Rod: ER4043 is a 5% Silicon Aluminum filler metal that is used primarily for welding Alu...

View full details$141.60 /5kg Pkt$28.32 / kg| /5kg Pkt -

TIG FILLER WIRE 316L STAINLESS STEEL 3.2MM

PN T31632QWS - Welding Supply Solutions$150.40 /5kg Pkt$30.08 / kg| /A molybdenum bearing Stainless Steel filler wire with low carbon content. It is corrosion resistant and suitable for welding molybdenum b...

View full details$150.40 /5kg Pkt$30.08 / kg| /5kg Pkt -

TIG FILLER WIRE 316L STAINLESS STEEL 1.6MM

PN T31616QWS - Welding Supply Solutions$127.20 /5kg Pkt$25.44 / kg| /TIG Filler Wire 316L Stainless Steel 1.6mm – Corrosion-Resistant Welding Solution for Critical Applications TIG Filler Wire 316L Stainless Steel 1....

View full details$127.20 /5kg Pkt$25.44 / kg| /5kg Pkt -

TIG FILLER WIRE 309L 2.4MM STAINLESS/MILD STEEL

PN T30924QWS - Welding Supply Solutions$130.50 /5kg Pkt$26.10 / kg| /$130.50 /5kg Pkt$26.10 / kg| /5kg Pkt -

TIG FILLER WIRE NICKEL BRONZE 1.6MM

PN NIBR16QWS - Welding Supply Solutions$486.75 /5kg Pkt$97.35 / kg| /Premium quality bronze filler rod recommended for the high strength braze welding of steel, cast and malleable irons.The standard ...

View full details$486.75 /5kg Pkt$97.35 / kg| /5kg Pkt -

TUNGSTENS ZIRCONIATED - ALUM WHITE 1.0MM

PN 700-0028QWS - Welding Supply Solutions$24.70 /pack of 10$2.47 / each| /Zirconiated tungsten electrodes (AWS classification EWZr-1) contain a minimum of 99.10% tungsten and .15 to .40% zirconium. A Zirconiated ...

View full details$24.70 /pack of 10$2.47 / each| /pack of 10 -

TUNGSTEN LANTHANATED 1.5% 3.2MM ECONOMY GOLD TIP

PN 32LQWS - Welding Supply Solutions$37.00 /pack of 10Translation missing: en.product.item.price.current $3.70 / each| /$37.00 /pack of 10Translation missing: en.product.item.price.current $3.70 / each| /Save 42% Save %pack of 10 -

TUNGSTEN LANTHANATED 1.5% 1.6MM GERMAN MADE GOLD TIP

PN 16WL20QWS - Welding Supply Solutions$55.20 /pack of 10Translation missing: en.product.item.price.current $5.52 / each| /The lanthanated tungsten electrodes are becoming more popular in the circle of welding in the world soon after they were developed, becaus...

View full details$55.20 /pack of 10Translation missing: en.product.item.price.current $5.52 / each| /Sold outpack of 10 -

TUNGSTEN LANTHANATED 2% 1.0MM ECONOMY GOLD TIP

PN 10LQWS - Welding Supply Solutions$12.00 /pack of 10$1.20 / each| /Lanthanated tungsten electrodes contain a minimum of 97.80% tungsten and 1.30 to 1.70% lanthanum, or lanthana. These electrodes have exce...

View full details$12.00 /pack of 10$1.20 / each| /pack of 10 -

TUNGSTEN PURE 3.2MM 175

PN 700.0016QWS - Welding Supply Solutions$88.70 /pack of 10$8.87 / each| /$88.70 /pack of 10$8.87 / each| /Sold outpack of 10 -

TUNGSTEN PURE 2.4MM 175 GREEN

PN 700.0012QWS - Welding Supply Solutions$49.60 /pack of 10$4.96 / each| /$49.60 /pack of 10$4.96 / each| /Sold outpack of 10 -

TUNGSTEN PURE 1.6MM 175 GREEN

PN 700.0007QWS - Welding Supply Solutions$29.90 /pack of 10$2.99 / each| /$29.90 /pack of 10$2.99 / each| /Sold outpack of 10 -

TUNGSTEN LANTHANATED 2% 4.0MM ECONOMY BLUE TIP

PN TR0014-40QWS - Welding Supply Solutions$98.40 /pack of 10$9.84 / each| /$98.40 /pack of 10$9.84 / each| /Sold outpack of 10 -

TUNGSTEN E3 PURPLE TIPPED 3.2MM

PN PTR0005-32QWS - Welding Supply Solutions$117.00 /pack of 10$11.70 / each| /$117.00 /pack of 10$11.70 / each| /Sold outpack of 10

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!