You're browsing Anti-spatter Products & Dips.

Anti-spatter Products & Dips

-

ANTISPATTER - UNIMIG AEROSOL 400G

PN UNIASUnimig$7.98 /Unit$7.98 / can| /UNIMIG Anti-Spatter Spray 400g (Aerosol) is a composition of advanced solutions that has been designed to minimise excessive spatter sticking to yo...

View full details$7.98 /Unit$7.98 / can| / -

BINZEL NOZZLE DIP 300G

PN 192.0058Genuine Binzel$6.99 / can| /FEATURES: 300g containers Pack Quantity: each Carton Quantity: 20 Antispatter Paste

$6.99 / can| / -

ANTISPATTER S-WELD AEROSOL 454G

PN 1450/454S-Weld$107.64 /12 Cans$8.97 / can| /S WELD SPATTER GUARDAnti-Spatter Aerosol SprayNon-flammable agent for the prevention of weld-spatter adhering to metal surfaces during the welding ...

View full details$107.64 /12 Cans$8.97 / can| /12 Cans -

WELDMAX SPATTERGO ANTISPATTER 20L

PN WMXAS20LWeldmax$269.00 / drum| /WELDMAX SPATTERGO Anti-Spatter liquid - MARKET LEADING PRODUCT!!! Weldmax™ SpatterGo™ provides high-level of protection from weld spatters and met...

View full details$269.00 / drum| /drum of 20Ltr -

500ML CONICAL HAND SPRAY BOTTLE

PN HZSACQWS - Welding Supply Solutions$4.95 / each| /Description: CONICAL ATOMISER BOTTLE

$4.95 / each| / -

CALLINGTON ANTISPATTER CALGUARD 20L

PN 1400/51CALLINGTON$131.23 / each| /CALGUARD ANTI SPATTER SPRAYWater-Based Calguard Anti-Spatter SprayEliminates spatter build up which results in poor gas flow causing pitting, poros...

View full details$131.23 / each| / -

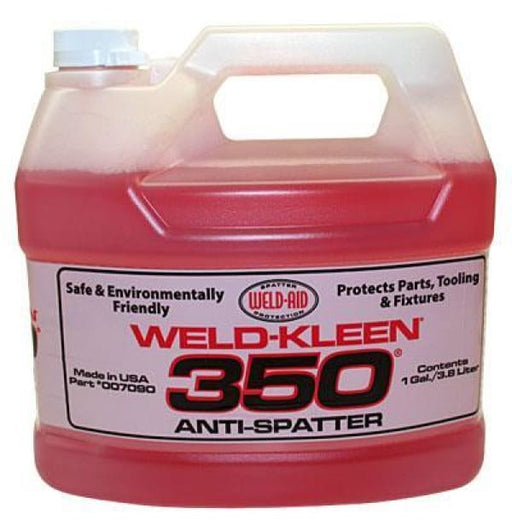

ANTISPATTER WELDKLEEN 350 - 3.8LTR

PN 007090WELD-AID$36.99 / each| /A SAFE, EFFECTIVE WATER-BASED PRODUCT DESIGNED FOR USE ON MOST BASE METAL APPLICATIONS. USED BY LEADING MANUFACTURERS, EFFECTIVE FOR USE IN ROBOT...

View full details$36.99 / each| / -

WELD-AID LUBE-MATIC LIQUID 5OZ

PN 007040Weld-Aid$21.83 / each| /Description: Helps feed all mild steel, fabricated, and core wires. Cuts rust and reduces wire drag by 60%. Use to re-lube black pa...

View full details$21.83 / each| / -

ANTISPATTER LANOTEC LANOLIN BASED 750ML

PN AS\SP-0750Lanotec$608.64 /Unit$25.36 /| /A non toxic, non flammable, welding anti-spatter. Does not contain Methylene Chloride Ideal for minimal clean up time Can w...

View full details$608.64 /Unit$25.36 /| /Sold out -

WELD AID NOZZLE CLEAN ANTISPATTER AEROSOL

PN 007022Weld-Aid$81.00 /Unit$13.50 / each| /Nozzle-Kleen is the world’s best-selling anti-spatter aerosol. It is the highest quality for most applications. Non-flammable and paintable. No flu...

View full details$81.00 /Unit$13.50 / each| / -

ANTISPATTER LANOTEC LIQUID 5LTR

PN AS/0005Lanotec$399.76 /Unit$99.94 / each| /A non toxic, non flammable, welding anti-spatter. Does not contain Methylene Chloride Ideal for minimal clean up...

View full details$399.76 /Unit$99.94 / each| / -

$8.10 /Unit$8.10 / can| /

-

UNIMIG ANTISPATTER 20L

PN UNIGUARD20Unimig$104.53 / can| /UNIMIG Anti Spatter Spray (Water-Based) is a composition of advanced solutions that has been designed to minimise excessive spatter sticking to you...

View full details$104.53 / can| /Sold out -

ANTISPATTER BOSSWELD PINK LIQUID 20LTR

PN 800050Bossweld$101.50 / each| /Water based, silicon free preparation used to prevent weld spatter sticking to MIG tips, nozzles & work pieces. Non toxic a...

View full details$101.50 / each| / -

AERODAG CERAMISHIELD 400ML

PN AC-PP-400Aerodag$57.23 / each| /Aerodag Ceramishield Innovative Protective Coating is a unique, ceramic protective coating that prevents metal spatter from adhering to we...

View full details$57.23 / each| / -

WELDMAX NOZZLE DIP 300G

PN WMXNOZDIPWeldmax$8.37 / each| /FEATURES: 300g metal container Pack Quantity: each Full Carton Quantity: 24 Antispatter Paste for tools, torches and welding components

$8.37 / each| / -

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!