You're browsing Tips & Components.

Tips & Components

-

CUTTING TIP TYPE 41 #6 HIGH SPEED OXY/ACETYLENE

PN 306069CigweldTranslation missing: en.product.item.price.current $25.70 / each| /Hi-speed cutting nozzles for use with cutting machines Size: 6HS Plate thickness: 6-8 Fuel gas flow l/min@100kpa: 6.0 ...

View full detailsTranslation missing: en.product.item.price.current $25.70 / each| /Save 20% Save % -

CUTTING TIP TYPE 44 OXY/LPG #12 12-20MM

PN 44-12QWS - Welding Supply Solutions$18.25 / each| /Oxygen and LPG cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence t...

View full details$18.25 / each| / -

CUTTING TIP TYPE 44 OXY/LPG #8 6-12MM

PN 44-8QWS - Welding Supply Solutions$18.25 / each| /Oxygen and LPG cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence t...

View full details$18.25 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 225-250MM

PN 5.5VVCHarris$33.40 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$33.40 / each| / -

CUTTING TIP TYPE 44 OXY/LPG #6 3-6MM

PN 44-6QWS - Welding Supply Solutions$18.03 / each| /Oxygen and LPG cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence t...

View full details$18.03 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 150-175MM

PN 3VVCHarris$33.40 / each| /Description Machine Cutting Tip 6290 VVC Style Two-piece Chrome-plated Alternative Fuel Cutting Tip Typical Application H...

View full details$33.40 / each| / -

CUTTING TIP TYPE 41 OXY/ACETYLENE #15 25-75MM

PN 41-15QWS - Welding Supply Solutions$12.35 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition temperature...

View full details$12.35 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 0-4MM

PN 5/0VVCHarris$35.16 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$35.16 / each| / -

CUTTING TIP TYPE 41 OXY/ACETYLENE #20 CIGWELD 100-125MM

PN 306050Cigweld$48.12 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition tem...

View full details$48.12 / each| / -

-

CIGWELD COMET HEATING TIP SHP2 OXY/LPG 36X12 13MM THREAD

PN 307119Cigweld$149.88 / each| /Provides efficient, economical high intensity heat, whilst providing excellent flame stability. The heavy copper head has been developed f...

View full details$149.88 / each| / -

HARRIS PROFESSIONAL GOUGING TIP ACET 6X13MM 48GB OUTLET

PN 6290 3GHarris$88.81 / each| /This range of Gouging Tips gives the end user terrific scope for repair or weld preparation. The quick starting and speed is a real featur...

View full details$88.81 / each| / -

CUTTING TIP TYPE 44 OXY/LPG #8 H/S

PN 306019QWS - Welding Supply Solutions$48.12 / each| /Oxygen and LPG high-speed cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence ...

View full details$48.12 / each| / -

LGPHS #1 AMERICAN TORCH TIP

PN LGPHS1ATT$13.56 / each| /Hi-speed fuel gas tip FEATURES Every Multi-Use tip fits every Multi-Use adapter. You need only one adapter for each torc...

View full details$13.56 / each| / -

CUTTING TIP TYPE 44 OXY/LPG #32 225-300

PN 44-32QWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $6.36 / each| /Oxygen and LPG cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence t...

View full detailsTranslation missing: en.product.item.price.current $6.36 / each| /Sold out -

HARRIS PROFESSIONAL LPG/PROPANE HEATING TIP 532 MJ/H

PN 22903HHarris$116.92 / each| /Professional Oxy/Propane The shape, performance, and characteristics of the flame are effected/controlled in some way by the tip. Harris...

View full details$116.92 / each| / -

LGPHS 3 AMERICAN TORCH TIP

PN LGPHS3ATT$13.56 / each| /Hi-speed fuel gas tip FEATURES Every Multi-Use tip fits every Multi-Use adapter. You need only one adapter for each torc...

View full details$13.56 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 175-200MM

PN 4VVCHarris$35.16 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$35.16 / each| / -

CUTTING TIP TYPE 41 OXY/ACETYLENE #24 150-200MM

PN 41-24QWS - Welding Supply Solutions$12.35 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition temperature...

View full details$12.35 / each| / -

CUTTING TIP 51 102 LOW SPEED ACET 100-150MM #6

PN 306121QWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $33.61 / each| /CIGWELD has a long established relationship with Koike Senso in Japan. Koike has developed a world-wide reputation as a leading manufactur...

View full detailsTranslation missing: en.product.item.price.current $33.61 / each| /Save 32% Save % -

CUTTING TIP TYPE 41 OXY/ACETYLENE #20 100-125MM

PN 41-20QWS - Welding Supply Solutions$12.95 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition temperature...

View full details$12.95 / each| / -

TYPE 44 GOUGING TIP - BENT #32 OXY/LPG

PN 44-32GBQWS - Welding Supply Solutions$46.67 / each| /Type 44 32GB LPG Bent Gouging Nozzle Two seated Gouging tip suitable for use with cutting attachment Size 32gb Bent Proven Consist...

View full details$46.67 / each| / -

CUTTING TIP TYPE 44 OXY/LPG #20 HI SPEED

PN 306023QWS - Welding Supply Solutions$54.38 /| /Oxygen and LPG cutting nozzles perform extremely well for certain applications. Due to less carbon in LPG, there is less slag adherence t...

View full details$54.38 /| / -

COMET TYPE MIXER - LARGE ACET OR LPG 13MM THREAD

PN 4-AHMXWeldclass$50.99 / each| /Mixers (For Brazing / Heating) Proven Quality Heating - Oxy/Acet or Oxy/LPG (Takes Heating Tube/Barrel) Application Info ...

View full details$50.99 / each| / -

CUTTING TIP TYPE 41 OXY/ACETYLENE #32 225-300MM

PN 41-32QWS - Welding Supply Solutions$12.35 / each| /Type 41 Acetylene Cutting Tips For 1600B and MG-242 cutting torch and cutting attachment One piece Length: 72mm

$12.35 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 125-150MM

PN 2.5VVCHarris$33.40 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$33.40 / each| / -

LGPHS #2 AMERICAN TORCH TIP

PN LGPHS2ATT$13.56 / each| /Hi-speed fuel gas tip FEATURES Every Multi-Use tip fits every Multi-Use adapter. You need only one adapter for each torc...

View full details$13.56 / each| / -

HARRIS PROFESSIONAL GOUGING TIP LPG

PN 4GGHarris$41.29 / each| /This range of Gouging Tips gives the end user terrific scope for repair or weld preparation. The quick starting and speed is a real featur...

View full details$41.29 / each| / -

HARRIS COPPER WELDING/BRAZING TIP ACET #5

PN 5090 5Harris$19.94 / each| /Description: 5090 Welding Tip Separable Acetylene Welding, Brazing and Soldering Tip Typical Application: For Light Duty W...

View full details$19.94 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 200-225MM

PN 5VVCHarris$33.40 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$33.40 / each| / -

HARRIS CUTTING TIP ACET PROFESSIONAL 200-300MM

PN 6290 6ACHarris$26.65 / each| /Oxy/Acetylene This Professional tip offers exceptionally quick starting for the operator. Combined with the ability to pull apart...

View full details$26.65 / each| / -

HARRIS CUTTING TIP LPG SUPER HIGH SPEED 75-125MM

PN 2VVCHarris$33.40 / each| /Propane, LPG, Natural Gas The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consum...

View full details$33.40 / each| /Sold out -

TYPE 551 WELDING TIP OXY/ACETYLENE #15 5.0MM

PN 551-15QWS - Welding Supply Solutions$21.95 / each| /Type 551 Oxygen/Acetylene Welding Tip Swaged Brazing and welding tips, made from copper, will fit onto industry standard 10mm Gas mix...

View full details$21.95 / each| / -

CUTTING TIP 51 102 LOW SPEED ACET 250-300MM #8

PN 306123QWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $33.61 / each| /CIGWELD has a long established relationship with Koike Senso in Japan. Koike has developed a world-wide reputation as a leading manufactur...

View full detailsTranslation missing: en.product.item.price.current $33.61 / each| /Save 37% Save % -

HARRIS CUTTING TIP CONTRACTOR ACET 25-75MM

PN 3690 2ACHarris$22.09 / each| /Oxy/Acetylene These two piece tips are very popular. Their flame characteristics, plus the ease of cleaning, make them ideal for ...

View full details$22.09 / each| / -

HARRIS CUTTING TIP HEAVY DUTY LPG 275-300MM

PN 7NHHarris$51.49 / each| /The Harris tip has become accepted world wide as “The Tip” for profile machine cutting. Flame shape, gas consumption, flame consistency an...

View full details$51.49 / each| / -

LGPHS #5 AMERICAN TORCH TIP

PN LGPHS5ATTTranslation missing: en.product.item.price.current $13.56 / each| /Hi-speed fuel gas tip FEATURES Every Multi-Use tip fits every Multi-Use adapter. You need only one adapter for each torc...

View full detailsTranslation missing: en.product.item.price.current $13.56 / each| /Save 22% Save % -

HARRIS CUTTING TIP ACET PROFESSIONAL 1-5MM

PN 6290 000ACHarris$37.39 / each| /Oxy/Acetylene This Professional tip offers exceptionally quick starting for the operator. Combined with the ability to pull apart for cle...

View full details$37.39 / each| / -

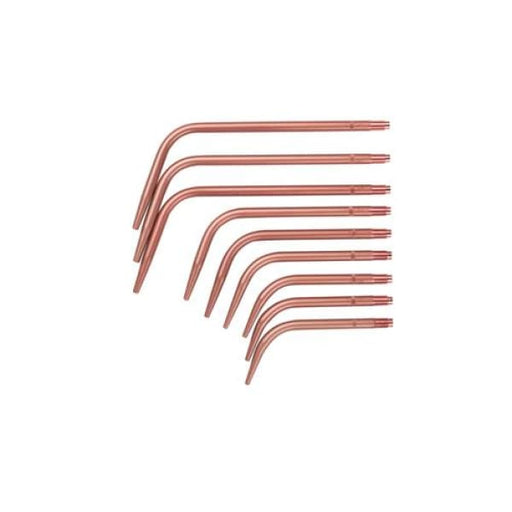

COMET TYPE HEATING TIP OXY/ACETYLENE 8X12 WITH BARREL 307007

PN 4-AH812Weldclass$33.79 / each| /Heating Tip Acetylene w/Tube Quality swaged copper heating tip Application Info For use with oxygen/acetylene gases ...

View full details$33.79 / each| / -

HARRIS CUTTING TIP LPG PROFESSIONAL 75-150MM

PN 4NXHarris$31.02 / each| /Professional Oxy/Propane/LPG The design of these Tips is superb and adds a new dimension to cutting, using Oxy/ LPG, Propane, Natural Gas....

View full details$31.02 / each| / -

CUTTING TIP TYPE 41 OXY/ACETYLENE #32 CIGWELD 225-300MM

PN 306052QWS - Welding Supply Solutions$48.12 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition tem...

View full details$48.12 / each| / -

HARRIS CUTTING TIP LPG PROFESSIONAL 15-25MM

PN 1NXHarris$31.02 / each| /Professional Oxy/Propane/LPG The design of these Tips is superb and adds a new dimension to cutting, using Oxy/ LPG, Propane, Natural Gas....

View full details$31.02 / each| / -

HARRIS CUTTING TIP HEAVY DUTY LPG 250-275MM

PN 6NHHarris$51.49 / each| /High Speed Cutting Tip Minimalize kerf; Increased cutting speeds, reduces heat input; High quality machine cuts, reduces afterwo...

View full details$51.49 / each| / -

HARRIS CUTTING TIP LPG PROFESSIONAL 0-5MM

PN 000NXHarris$31.02 / each| /6290NX is the most common type of Harris style cutting tip for use with oxygen & LPG, propane or natural gas. Harris style 6290NX ha...

View full details$31.02 / each| / -

HARRIS CUTTING TIP HEAVY DUTY LPG 250-275MM

PN 5NHHarris$21.83 / each| /6290-NH Cutting Tips HARRIS Style: Two pieces Tips for cuts from 225 TO 250mm.

$21.83 / each| / -

CUTTING TIP TYPE 54 106 LOW SPEED LPG 3 SEAT 50-100MM #5

PN 306102QWS - Welding Supply Solutions$28.63 / each| /CIGWELD has a long established relationship with Koike Senso in Japan. Koike has developed a world-wide reputation as a leading ma...

View full details$28.63 / each| / -

CUTTING TIP 51 102 LOW SPEED ACET 5-10MM #0

PN 306115QWS - Welding Supply Solutions$41.82 / each| /CIGWELD has a long established relationship with Koike Senso in Japan. Koike has developed a world-wide reputation as a leading ma...

View full details$41.82 / each| / -

CIGWELD 41-64 OXY/ACETYLENE GOUGING BENT

PN 306037Cigweld$76.95 / each| /Nozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition tem...

View full details$76.95 / each| /

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!