You're browsing Wire Feeder & Machine Spares.

Wire Feeder & Machine Spares

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

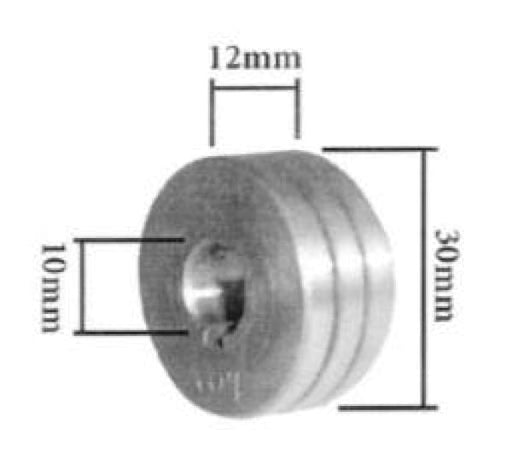

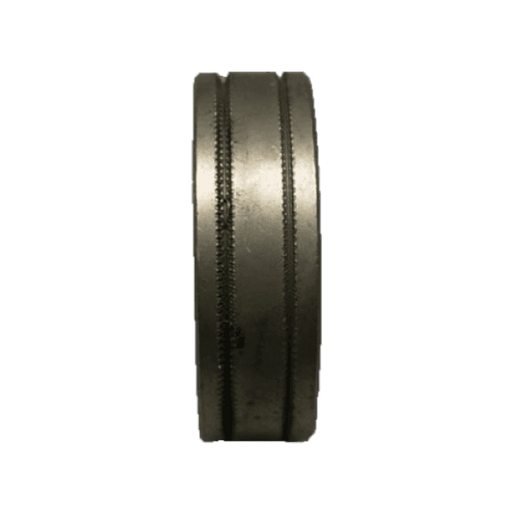

WIREFEED ROLLER 30/22 0.8/1.0MM KNURLED

PN WFR30220810FXQWS - Welding Supply Solutions$25.99 / each| /KNURLED drive rollers in the 0.8mm-1.0mm size 30*22*10mm

$25.99 / each| / -

WIREFEED ROLLER 30/22 1.0/1.2MM V GROOVE

PN WFR30221012VQWS - Welding Supply Solutions$25.99 / each| /V GROOVE WIREFEED ROLLER 30/22 1.0/1.2MM

$25.99 / each| / -

WIREFEED ROLLER 40/22 0.8/1.0MM V GROOVE

PN WFR40221008VQWS - Welding Supply Solutions$46.58 / each| /V GROOVE WIREFEED ROLLER 40/22 0.8/1.0MM

$46.58 / each| / -

WIREFEED ROLLER 40/32 0.8/1.0MM V GROOVE

PN WFR40320810VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $46.58 / each| /WIREFEED ROLLER 40/32 0.8/1.0MM V GROOVE

Translation missing: en.product.item.price.current $46.58 / each| /Save 29% Save % -

WIREFEED ROLLER 30/22 1.2/1.6MM KNURLED

PN WFR30221216FXQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $25.99 / each| /WIREFEED ROLLER 30/22 1.2/1.6MM KNURLED

Translation missing: en.product.item.price.current $25.99 / each| /Save 20% Save % -

WIREFEED ROLLER 40/22 1.0/1.2MM V GROOVE

PN WFR40221012VQWS - Welding Supply Solutions$46.58 / each| /V GROOVE WIREFEED ROLLER 40/22 1.0/1.2MM

$46.58 / each| / -

WIREFEED ROLLER 30/22 0.6/0.8MM V GROOVE

PN WFR30220608VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $25.99 / each| /V GROOVE WIREFEED ROLLER 30/22 0.6/0.8MM

Translation missing: en.product.item.price.current $25.99 / each| /Save 65% Save % -

WIREFEED ROLLER 40/22 0.6/0.8MM V GROOVE

PN WFR40220608VQWS - Welding Supply Solutions$46.58 / each| /V GROOVE WIREFEED ROLLER 40/22 0.6/0.8MM

$46.58 / each| / -

WIREFEED ROLLER NATTA FX 1.2/1.6MM V

PN WFRNFX1216VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $32.40 / each| /WIREFEED ROLLER NATTA FX 1.2/1.6MM V

Translation missing: en.product.item.price.current $32.40 / each| /Save 30% Save % -

WIRE FEED ROLLER 1.0/1.2MM V 37 X 19 X 12MM

PN WFRPTS1012VQWS - Welding Supply Solutions$41.18 / each| /WIRE FEED ROLLER PTS 1.0/1.2V

$41.18 / each| / -

WIREFEED ROLLER 30/22 0.8/1.0MM U GROOVE

PN WFR30220810UQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $25.99 / each| /U GROOVE WIREFEED ROLLER 30/22 0.8/1.0MM

Translation missing: en.product.item.price.current $25.99 / each| /Save 65% Save % -

$164.46 / each| /

-

-

FRONIUS SPRING TPS 2700 DRIVE ROLL ASSY

PN 42.0404.0264FroniusTranslation missing: en.product.item.price.current $1.88 / each| /Translation missing: en.product.item.price.current $1.88 / each| /Save 22% Save % -

-

FRONIUS DRIVE ROLLER 1.0V T

PN 42.0001.1585FroniusTranslation missing: en.product.item.price.current $71.58 / each| /Translation missing: en.product.item.price.current $71.58 / each| /Save 42% Save % -

BINZEL GUIDE TUBE 200MM BRASS

PN 129.0461Genuine Binzel$9.04 / each| /Abicor Binzel® Steel Guide Tube fits at the drive roller end of your mig machine, Teflon or carbon graphite liner slides inside the guide ...

View full details$9.04 / each| / -

-

WIREFEED ROLLER 40/22 0.9/1.0MM V GROOVE

PN WFR40220910VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $19.00 / each| /V GROOVE WIREFEED ROLLER 40/22 0.9/1.0MM

Translation missing: en.product.item.price.current $19.00 / each| /Save 59% Save % -

WIREFEED ROLLER 40/22 1.0/1.2MM KNURLED

PN WFR40221012FXQWS - Welding Supply Solutions$51.60 / each| /WIREFEED ROLLER 40/22 1.0/1.2MM KNURLED

$51.60 / each| / -

-

-

WIREFEED ROLLER NATTA 1.0/1.2MM V

PN WFRN1012VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $32.40 / each| /WIREFEED ROLLER NATTA 1.0/1.2MM V

Translation missing: en.product.item.price.current $32.40 / each| /Save 30% Save % -

FRONIUS ROLL FEEDER PINS

PN 42.0405.0119FroniusTranslation missing: en.product.item.price.current $8.47 / each| /BOLT FEED UNIT NEW

Translation missing: en.product.item.price.current $8.47 / each| /Save 41% Save % -

WIREFEED ROLLER 40/22 1.2/1.6MM KNURLED

PN WFR40221216FXQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $24.00 / each| /WIREFEED ROLLER 40/22 1.2/1.6MM KNURLED

Translation missing: en.product.item.price.current $24.00 / each| /Save 26% Save % -

FRONIUS CENTRAL CONNECTOR FSC VR 5000

PN 43.0004.4059Fronius$102.94 / each| /The Fronius System Connector (FSC) conveys all the media required during the welding process, ensures maximum process stability through i...

View full details$102.94 / each| / -

-

BINZEL GUIDE TUBE 3.0X200MM

PN 129.0395Genuine Binzel$9.57 / each| /Abicor Binzel® Steel Guide Tube fits at the drive roller end of your mig machine, Teflon or carbon graphite liner slides inside the guide ...

View full details$9.57 / each| / -

-

KEMPPI ROLLER SELECTOR PLATE SL500

PN 4266100Kemppi$26.24 /pack of 4$6.56 / each| /Kemppi Groove Selector Washer

$26.24 /pack of 4$6.56 / each| /pack of 4 -

WIREFEED ROLLER 40/28 0.8/1.0MM V GROOVE

PN WFR40280810VQWS - Welding Supply SolutionsTranslation missing: en.product.item.price.current $35.64 / each| /WIREFEED ROLLER 40/28 0.8/1.0MM V GROOVE

Translation missing: en.product.item.price.current $35.64 / each| /Save 40% Save % -

WIREFEED ROLLER 30/14 1.2/1.6MM FX-GR WELDMAX 350B/500B S1

PN WFR30121216FXWELDMAX$46.00 / each| /Wire feed rollers to suit Weldmax Black Thunder Series 350B and 500B wire feeders 30mm OD 10mm ID 12mm wide 3.7mm locator pin hole diameter ...

View full details$46.00 / each| / -

WIREFEED ROLLER 37/19 0.9/1.2MM V GROOVE

PN WFR37190912VQWS - Welding Supply Solutions$47.65 / each| /V GROOVE WIREFEED ROLLER 37/19 0.9/1.2MM

$47.65 / each| / -

WOODRUFF KEY, HALF MOON SHAPE

PN WK2QWS - Welding Supply Solutions$3.24 / each| /Half moon shaped Woodruff key that is inserted into curved slot in shaft. The advantage of a woodruff key is that once the key is properly...

View full details$3.24 / each| / -

-

TBI INLET GUIDE 1.2-1.6 STEEL

PN 186P102041Tbi$22.08 /pack of 2$11.04 / each| /TBI INLET GUIDE 1.2-1.6 STEEL

$22.08 /pack of 2$11.04 / each| /pack of 2 -

-

TBI CENTRAL ADPTR GAS AXIAL 600MM AM6000

PN 701P041117Tbi$99.91 / each| /Central adaptor machine side, gas axial, cpl. (wire = L 600mm)

$99.91 / each| / -

$1.57 / each| /Sold out

-

-

-

-

WIREFEED ROLLER 30/14 0.8/1.0MM V-GR WELDMAX 350B/500B S1

PN WFR30120810VWELDMAXTranslation missing: en.product.item.price.current $18.10 / each| /Translation missing: en.product.item.price.current $18.10 / each| /Sold out -

$20.64 / each| /

-

-

-

-

$46.00 / each| /

Stay up to date with QWS

Join our mailing list to receive specials, discounts & technical information!