Shedding Light on Laser Welding Safety: A Beginner's Guide to Precision with Precaution

Laser welding is a cutting-edge technology that has revolutionized the welding industry, offering precision and efficiency that traditional welding methods often cannot match. However, with the many benefits of laser welding come unique safety challenges and potential exposure risks. In this blog, we will explore the critical aspects of laser welding safety and exposure, shedding light on the precautions that must be taken to protect workers and the environment.

Understanding Laser Welding

Before we delve into safety measures, it's crucial to understand the basics of laser welding. Laser welding is a high-energy process that uses a focused laser beam to fuse materials together. The intense heat generated by the laser creates a weld seam, which can be exceptionally narrow and deep. While laser welding is highly efficient and precise, it also generates high-intensity light and heat, posing risks to workers and the environment.

Proper training is essential for laser welding operators. They should be well-versed in laser safety, including the potential hazards, emergency procedures, and safe operating practices. Regular refresher courses can help keep knowledge up to date.

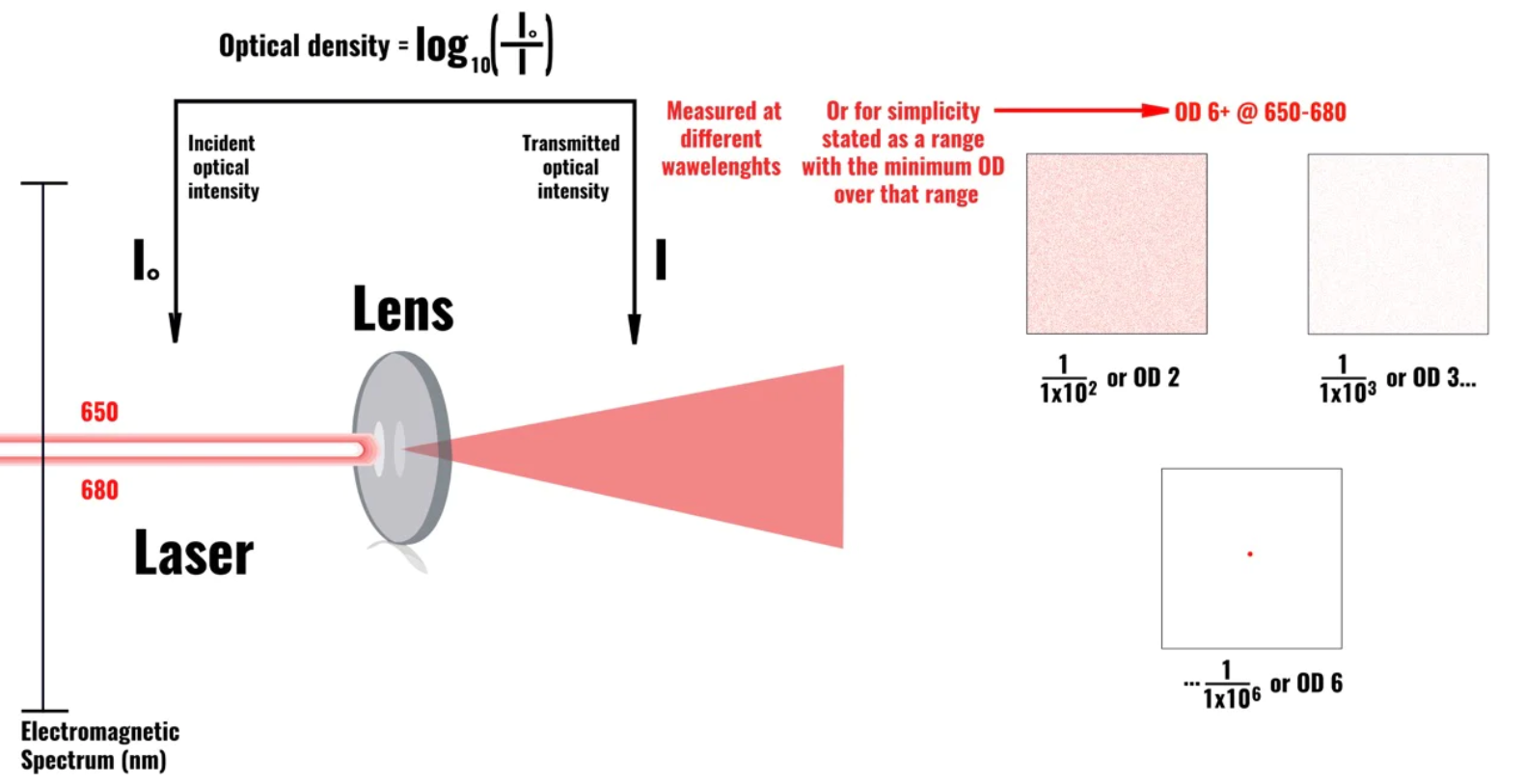

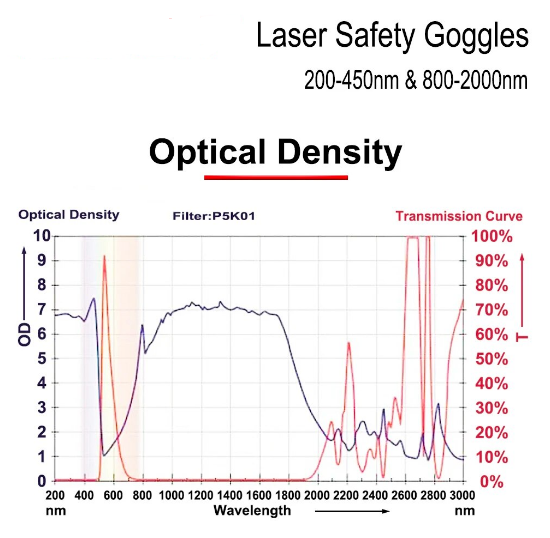

What is OD (Optical Density) Laser Safety?

Optical Density (OD) in laser safety is the amount of light attenuated[i] by the lens of the particular wavelength that is being measured, it measures the ability of a material, such as laser safety eyewear or protective barriers, to attenuate or reduce the intensity of laser light. It is a crucial factor in ensuring that individuals working with or around lasers are adequately protected from potential harm.. The required OD determined by the World Laser Safety in the USA found in ANSI Z136.1 are dependent upon several factors, including the wavelength of the laser. The standards were created through research based on how different wavelengths have different biological impacts.

Below is an example for how to read the shorthand notation for optical density and the attenuation of energy passing through a given filter.

Please note, each wavelength will have a different optical density. For simplicity, it is stated as a range of wavelengths.

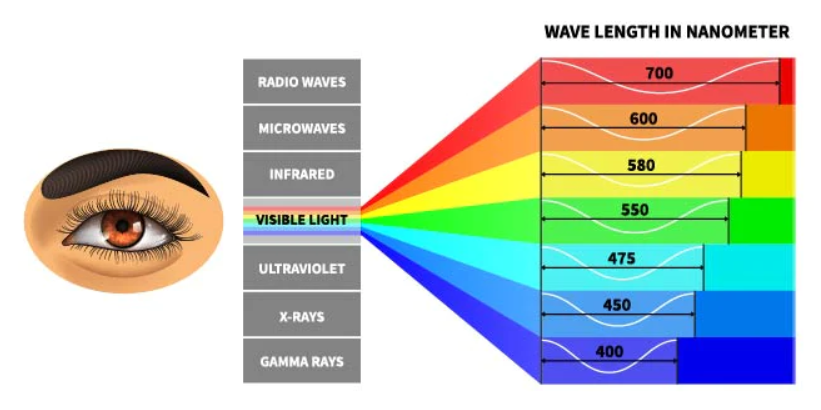

Wavelength is the first parameter needed to begin assessing the type of laser safety protection needed.

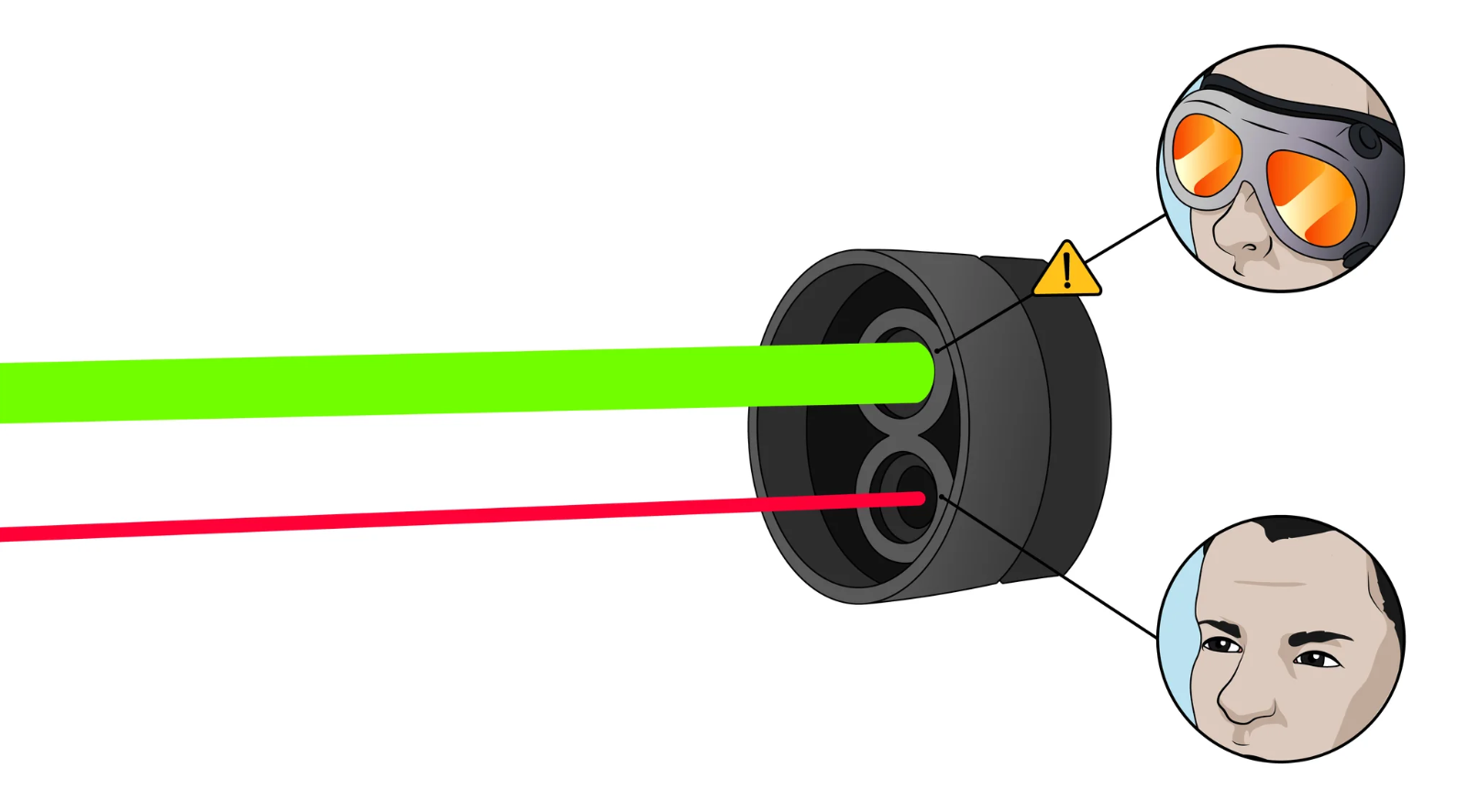

There are typically two wavelengths associated with a laser:

1. The aiming beam wavelength - Typically "eye safe" | depicted in the image below as red.

2. The operating beam wavelength - the operating beam requires proper laser safety protection | depicted in the image below as green.

Operating Beam Laser vs Aiming Beam Laser (Typically Eye-Safe)

The formula for calculating optical density is:

OD =−log10

(T )

Where:

> OD is the optical density,

> T is the transmission of the material, representing the fraction of incident light that passes through.

The higher the optical density, the greater the ability of the material to block or absorb laser light. A higher OD is generally associated with better protection.

When selecting laser safety eyewear, it's essential to choose lenses with the appropriate optical density for the specific laser wavelength and power level you are working with.

Different lasers emit light at different wavelengths, and protective eyewear is designed to block or attenuate light at specific wavelengths.

For example, if you are working with a Class 3B or Class 4 laser, which can cause eye injury, you would need laser safety glasses with a high optical density that matches the laser's wavelength.

The glasses should have an OD sufficient to reduce the laser intensity to safe levels for the eyes.

It's important to consult the laser safety standards and guidelines specific to your application and laser system to determine the appropriate optical density required for adequate protection. Always ensure that the laser safety eyewear or protective barriers you use are certified for the specific laser hazards you may encounter.

Watch the Video

The aiming beam is to aid the user in positioning the operating laser beam. Generally, the aiming beam will be low powered and typically red. Do not look directly at any laser including the aiming beam. A common use case for an aiming beam is a laser pointer. For more information on laser safety with an operating beam vs an aiming beam.

If you are in doubt whether or not your aiming beam is eye-safe for diffused viewing, please check with your laser safety officer or call us before making any assumptions. Recently our team has come across wavelengths utilized for aiming beams that are inappropriate without proper laser safety protection.

Never look at any laser (including the aiming beam) directly. Stand behind the beam while viewing it, and do not bring your eyes near the axis during alignment or any other operation with lasers. All laser safety PPE is for unintentional direct and diffused viewing only.

If you are hit with any laser in the eye, look away immediately.

If the alignment beam exceeds the MPE, use proper alignment eyewear (where the MPE threshold is not exceeded factoring appropriate exposure duration). Attenuating the laser to a point it cannot be seen is an issue. So, make sure to align the laser correctly.

Laser safety alignment eyewear should be used at all times. Always be safe when dealing with lasers.

Having proper personnel with appropriate training and standard operating procedures during the alignment process are proper laser safety amongst several other laser safety controls.

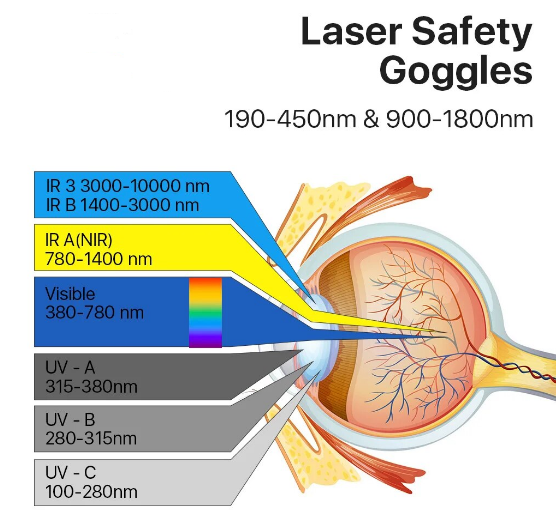

Many lasers are within the range of the visible light spectrum of 380 nm (violet) and 740 nm (red). Individuals also need protection from lasers which emit Ultra-Violet light, (lower wavelength than visible light) and infrared light (higher wavelengths than visible light on the magnetic spectrum). It is important to know the wavelength of the laser you’re working with - different lasers require different degrees of protection as outlined in ANSI.