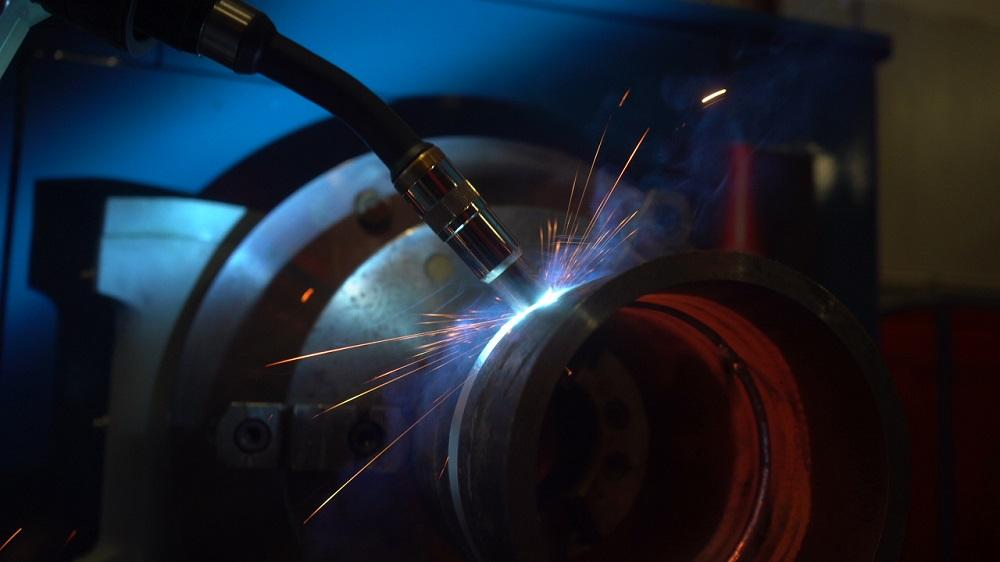

Prevent & Fix Porosity in Gasless ('MIG') Welding

What is porosity in welding?

Porosity is the presence of cavities in the weld metal caused by the freezing in of gas released from the weld pool as it solidifies.

It does not only look terrible, but it also weakens the weld joint significantly.

If you’re having Porosity problems with gasless welding wire, then this might interest you.

Below is a checklist to help you identify the causes of porosity in your weld:

Polarity

Always check the Polarity, the wrong polarity will cause porosity and could trigger other problems too. Check that your earth lead is connected to positive (+) and the torch/wire to negative (-).

Pull Your Weld

Pull instead of push, welding with gasless and flux-cored wires, you should always drag the torch (like stick electrode welding), so that the torch is pointing back at the weld pool. A helpful way to remember this is "if there's slag, you drag".

This is the opposite to MIG welding (with gas) where you would normally push the torch.

Machine Settings & Technique Adjustment

While the arc may feel smoother with a high voltage, one of the most common causes of porosity is too much voltage (heat).

Try turning down the voltage setting on your welder. (Depending on the material thickness, you may also want to consider changing to a larger diameter wire - this will effectively reduce your voltage whilst allowing a higher weld deposition rate).

Also - the following adjustments can also help to eliminate or reduce porosity.

• Increase wire speed

• Increase wire stick out length

• Decrease travel angle (angle the torch closer to a perpendicular position)

Note: Some gasless wires are more sensitive to variations in settings than others and are more prone to porosity problems. One of the reasons why many welders prefer Hyundai E71T-11 / E71-TGS gasless wire because it is very tolerant to variations in machine settings and characteristics and is very resistant to porosity and other issues.

Keep Away from Extremely Dirty & Contaminated Metal

Gasless wire is usually more tolerant towards dirt, rust, paint, and surface imperfections than standard MIG welding (with gas), however the fact remains that poor surface condition can still cause porosity and other problems.

Also note that sometimes the parent metal can look relatively clean but has been contaminated with grease or other substances that have penetrated the steel.

If the material being welded is dirty or if you suspect it has been contaminated, prepare a test piece that is completely clean and has not come into contact with oil. If necessary, grind or linish the test piece to ensure contamination is completely removed. Run some test welds on the test piece – if the test welds are free of porosity, then it is very likely that surface contamination is the problem. If the test still exhibits porosity, then check the other potential causes in this article.

Some gasless wires are “fussier” than others about surface condition. Hyundai E71T-11 / E71-TGS gasless wire is very tolerant to imperfect surfaces, making it very easy and hassle-free to use.

Confirm Good Connection of Earth Lead & Clamps

The integrity of the earth clamp and earth connection is critical. Defects at any point along the ‘current path’ (which includes the earth) can contribute to issues like porosity.

Check the earth lead connection to the welder, the earth cable, the earth clamp, and the earth clamp connection to the job – and rectify any loose connections, worn components and defects.

If your earth clamp is the 'cheap & nasty' type, we strongly recommend that you upgrade it. The EG600 earth clamp is one of our most popular models, it's very robust, super easy to fit, suits most welders... and most importantly, designed to provide a very reliable earth connection.

Also note that the earth clamp should be as close to the weld location as possible, to provide the most direct ‘current path’.

Refrain From Welding in Windy Conditions

Yes, gasless wire is often used in the field and is certainly the best choice for windy conditions. However, if the wind is particularly strong this can cause porosity.

To shield the weld, gasless wire relies on both a slag system and the gases produced from chemical reactions in the arc. Strong wind can interfere with this gas shield, exposing the molten metal to the atmosphere and cause porosity.

If you suspect this might be happening, run some test welds in a sheltered area.

Always Choose to Use High Quality Wires

Compared to standard solid wire, Gasless wire is much more prone to quality variations from one brand to another.

This is because the performance of the wire is very dependent on the formula of the flux inside the wire, as well as the integrity of the filler metal. While different gasless wire brands may comply with the same classification, each manufacturer will have their own formula and therefore each wire will behave differently.

If the wire you are using is proving difficult to run, try Hyundai E71T-11 / E71-TGS gasless wire. Thousands of Aussie welders’ rate Hyundai E71T-11 / E71-TGS gasless wire as the best, most user-friendly gasless wire they have ever used... we'd love to get your feedback as well!

VIEW OUR RANGE OF HIGH QUALITY MIG WIRE FLUX CORED

Related Posts

PROTECTING THE WELDER FROM OZONE: A SCIENTIFIC STUDY

One objective of this study was to understand the levels of ozone that an unprotected welder may be exposed to across a variety of different welding processes and whether a Welding Helmet with a Powered Air Purifying Respirator (PAPR) was an effective control in protecting the welder from exposure to ozone.

AUTOMATION: THE FUTURE OF WELDING

The world is evolving, and technology is becoming increasingly integrated into all aspects of our lives. From streaming services to self-driving cars, automation has made its way into almost every industry. So why should welding be any different? Let’s take a look at the advantages of welding automation and explore why it might be the future of welding.

Reticulated Gas Pipe System

Weld Shielding gases, Oxygen & Fuel, Scientific & Medical Gases can all be reticulated for Commercial, Safety and convenience benefits. When gases are used in significant volumes, a centralized gas delivery system is a practical necessity. A well-conceived delivery system will reduce operating costs, increases productivity, and enhance safety.