USED FRONIUS TPS4000 TWIN / TANDEM WIRE WELDING PACKAGE

High Speed welding and large production cost savings start here.

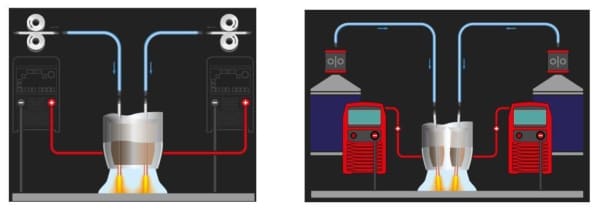

The process involves high performance MIG/MAG welding using two wire electrodes. It is only used in automated applications, and is ideal for increasing welding speed as well as deposition rate. With a simple connection to a torch holder - this enables fast and continuous welding to take place utlising the travel of a straight-line carriage or welding turntable.

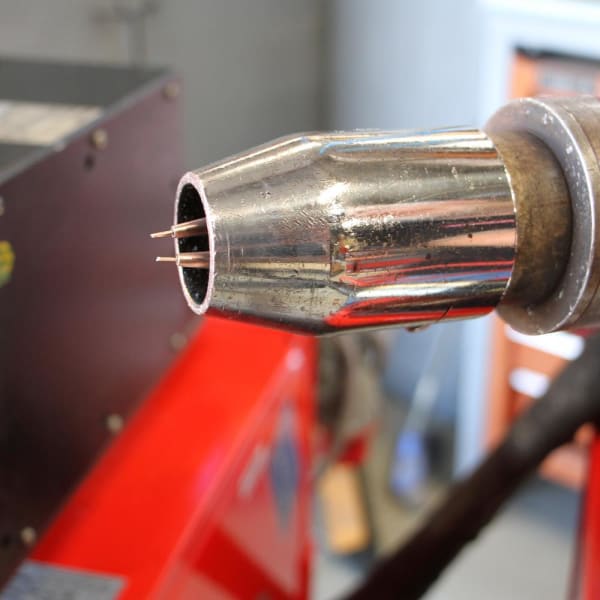

During tandem welding two wire electrodes are melted at the same time. These are routed through two electrically isolated contact tips, i.e., the potentials are separate. As a result, the arcs can be controlled independently and, despite differing outputs, can be precisely coordinated.

Tandem Wire Package is supplied ready to weld... including:

- 2x External Wire feeders

- 2x Interconnecting cables

- 2x TPS4000 Powersources

- 1x Twin Wire welding torch - Heavy duty watercooled

- 1x remote control pendant

- Super Heavy duty earth clamp and leads

- Gas regulator

- 2x 3phase plug and 4mtr cable

- Tested and Tagged.

- 6month warranty

- Delivery to your workshop for all customers in Brisbane, Gold Coast, Sunshine Coast regions, and some other South East Queensland areas.

- Freight can be arranged to other areas at very competitive rates....check us for rates.

The Advantages of Twin / Tandem Welding at a Glance

- Two separate contact tips à each contact tip can be controlled independently]

- Extremely high welding speeds (2 m/min +, depending on the welding position)

- Extremely high deposition rate (22 kg/h +)

- Can be used on thin and thick sheets

- High potential for cost savings

- Easy to operate

- Different wire feed speeds possible between the lead (front) and trail (rear) wire electrode

- Synchronizing of both arcs promotes process stability